Wheel Hub Manufacturer Since 2010

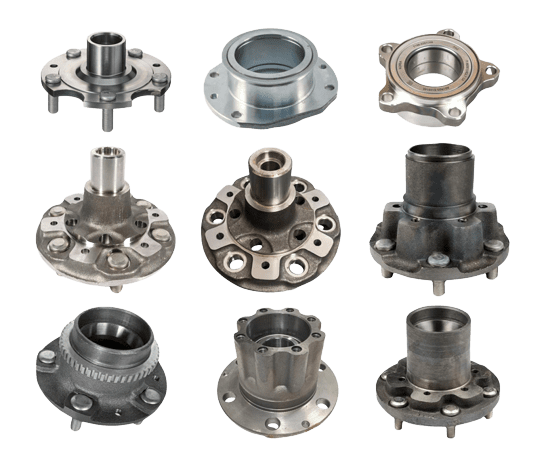

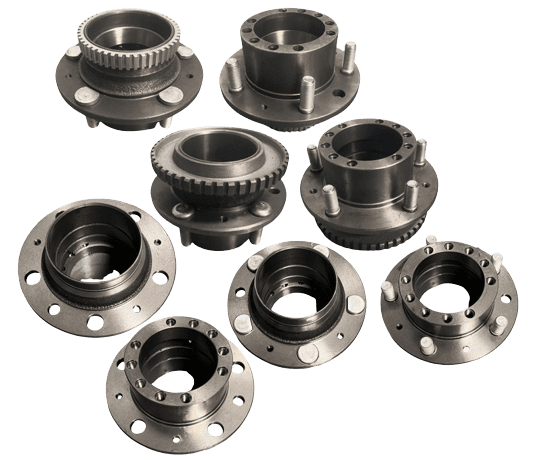

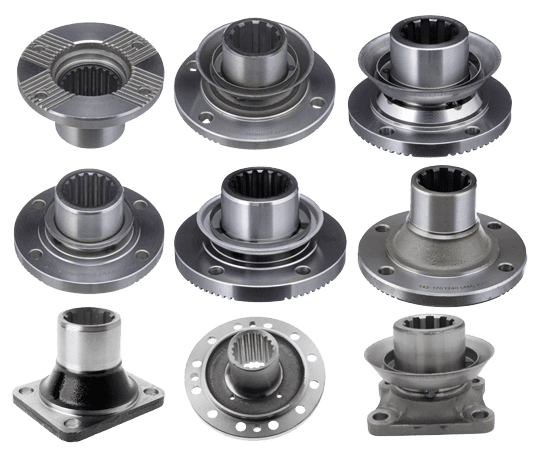

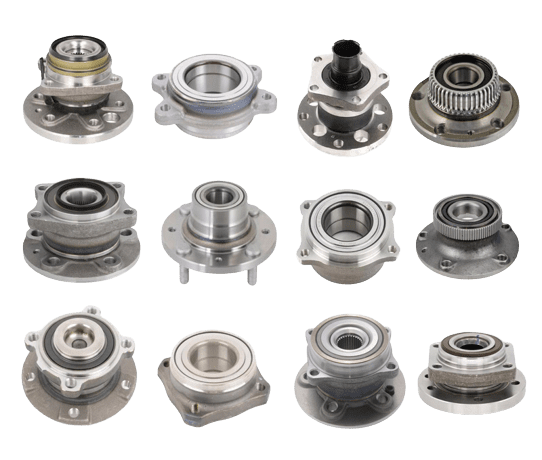

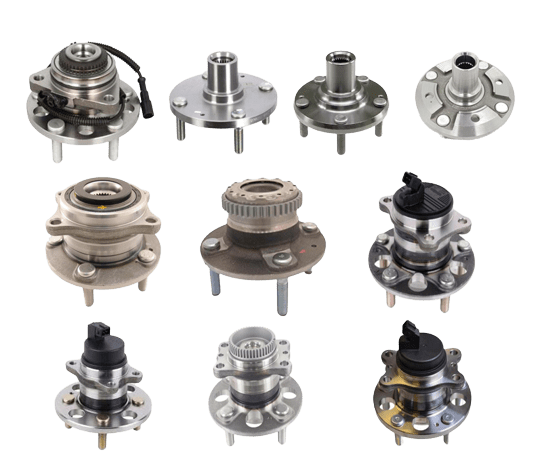

More than 1000 kinds of models, almost have what you need.

Huge capacity to ensure on-time delivery.

15 years in the industry, with extensive production experience.

Trusted by dozens of world-class brands and organizations of all sizes

Who We Are

Wheel bearing & hub assembly manufacturer

Wana Auto Parts Co., Ltd owned this site wheelhubfactory.com. We manufacture high-performance wheel bearings and hub assemblies. Our factory is located in Yuhuan City, the biggest auto chassis parts production base in China, and all the products are under strict quality control before delivery. Our experienced technicians are always ready to provide the necessary services for you.

We're No.1 Wheel Hub Factory

- Over 2800 models in range

- $20 million annual output

- Capacity 10,000 sets per day

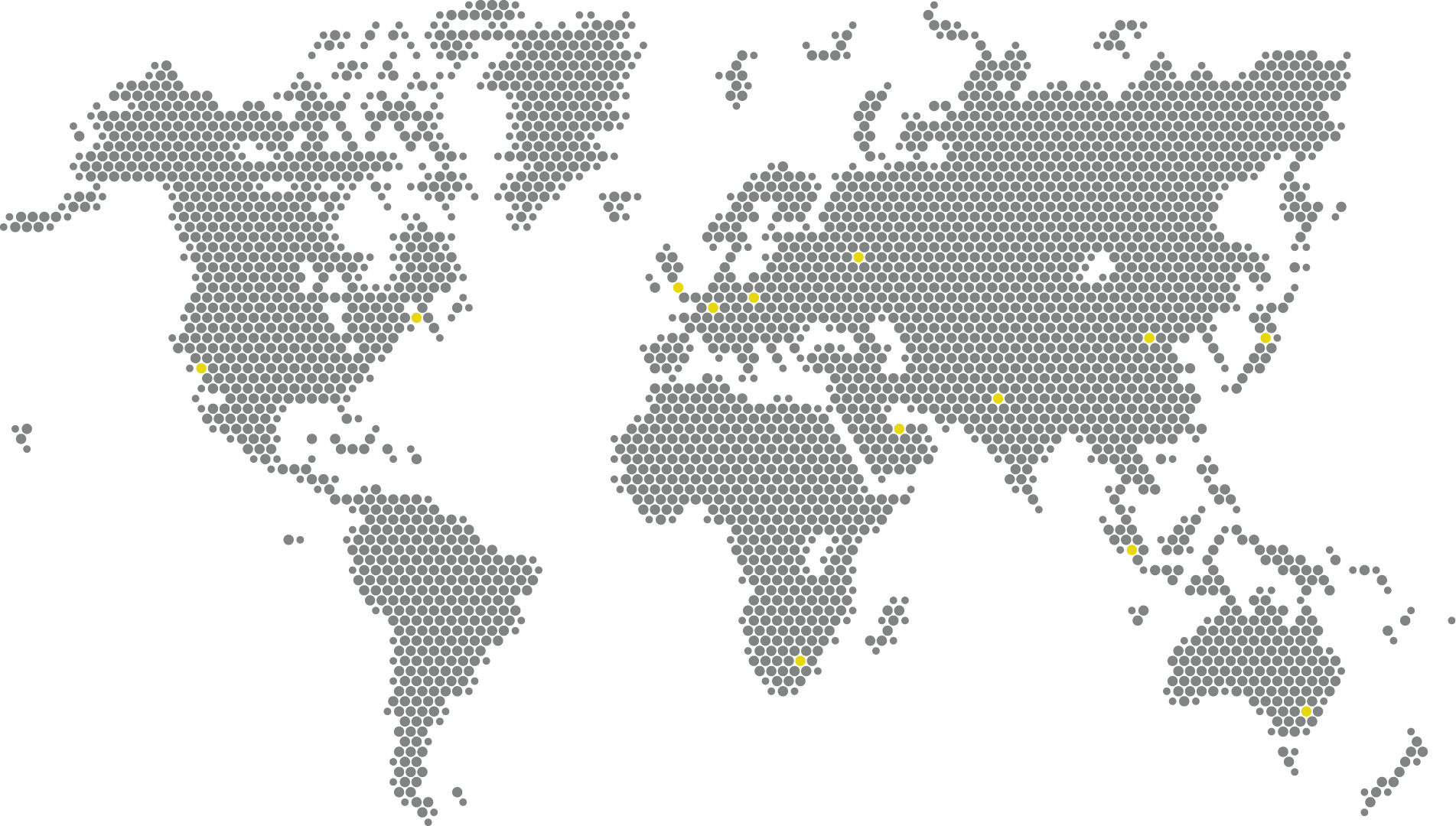

We Spread Around The World

After 13 years of development, we have many brand customers worldwide; their trust is the foundation of our product. We provide professional services to ensure the best experience for them. In the future, we will continue to progress and strive to create more value for our customers!

North America

South America

Europe

Middle East

Australia

Asia

Our Advantages

From Roughs to Assemblies Are All Made by Us

Extreme cost control, strict quality control, rich market experience, and good communication are incomparable to any factory.

2 years or 80,000 km warranty.

Our solutions for your market and brand

After 13 years of development, we have more than 2800 models; regardless of various car models, you can find almost all the wheel bearings and hubs you need from us. In addition, we are constantly developing new wheel hubs to meet the market’s ever-changing needs.

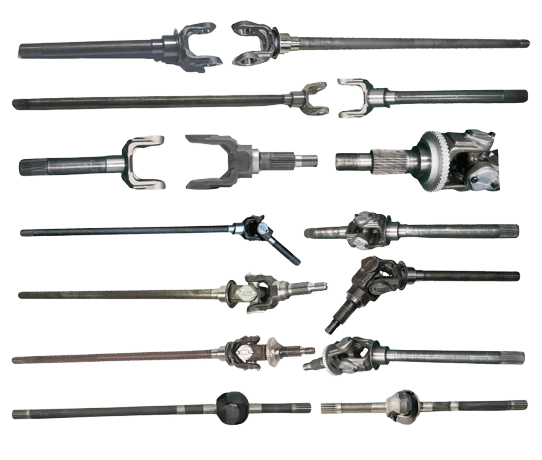

GAZ CV Joint Steering Knuckle Joint

Steering knuckle joint of GAZ, GAZelle, Gazel cv joint

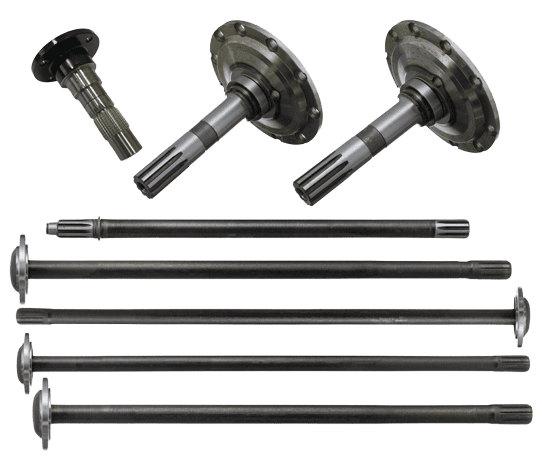

GAZ Axle Shafts Half Shafts

Front and rear axle shafts and half shafts for GAZ, GAZelle, Gazel

UAZ CV JOINTS Steering Knuckle Joints

CV Joints and steering knuckle joints for UAZ cars and trucks

UAZ Axle Shafts Half Shafts Driven Wheel Reducer

Front and rear axle shafts, half shafts, and driven wheel reducer for UAZ cars and trucks

UAZ KAMAZ Primary Shaft Bearing Covers

Primary shaft bearing covers for UAZ and KAMAZ cars and trucks

Japanese vehicle’s wheel hub

TOYOTA, LEXUS, HONDA, NISSAN, INFINITI, MAZDA, MITSUBISHI, SUZUKI, ISUZU, SUBARU, DAIHATSU

American vehicle’s wheel hub

CHRYSLER, DODGE, GM, CHEVROLET, CADILLAC, BUICK, PONTIAC, HUMMER, GMC YUKON, JEEP, FORD, TESLA

Why Choose Us

What we can bring to your business?

How did we grow from a small workshop to the size we are today?

The first is that we put our customers first, only letting them make money so that their business grows bigger and bigger, and we will have more and more orders.

The second is that our employees get higher and higher salaries, so we can always attract more and more talents to join us.

Finally, we are able to continuously develop new products in response to market changes, which allows us to keep pace with the market.

Let's be great together

Unlock Your Competitive Edge: Inquire Now for Unmatched Wheel Hub Solutions!

We have been doing only one thing for the past 13 years. This is to “make good wheel bearings and hub assemblies”; we will continue to do this in the future.

Why Us?

Not all wheel hubs are the same; let’s talk about our stand-out.

High Grade Steel Bearings

Our bearings are high-strength GCR15 steel, subjected to a proprietary process to achieve maximum hardness, and finally treated with a G-10 finish.

High-grade GCR15 steel prevents premature failure due to extreme temperatures and high loads during normal operating conditions. G-10 resin is among the most challenging “glass fiber resins” available. Non-treated steel bearings showed signs of scoring after only a few thousand miles of simulated testing at various speeds. At the same time, treated steel bearings lasted over one hundred thousand miles of simulated testing.

High-Quality Grease

We use Kyodo Yushi AFI grease, made in Japan and specially designed for wheel bearings; it has a long lifespan and performs well in extreme weather.

Without the grease, the best bearing in the world would fail very quickly. So, it’s essential to use high-quality grease that will last the life of the bearing.

Triple & Quadruple Lip Sealing

We use triple and quadruple lip sealing technology. This technique uses high-temperature-resistant rubber to achieve maximum bearing protection against dust, water, and road debris.

10/08F steel plates+NBR rubber.

10.9 Grade Bolts

Our wheel hubs use 10.9-grade bolts; the pulling force can reach 1000 Nm, far exceeding the international standard of 750 Nm. This makes the quality of our bolts much better than other brands in the market.

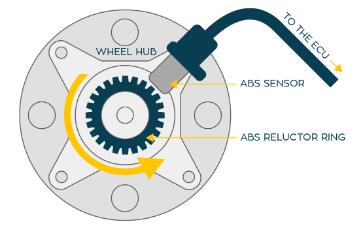

OEM Specification ABS Sensors

ABS sensors used with our Wheel Hub Assemblies are manufactured with premium wire casings with 99.90% pure copper on the internal wiring for excellent electrical conductivity and optimal performance. In addition, our sensors are rigorously tested using the latest state-of-the-art equipment to ensure that the signal waves meet or exceed OE specs and Electromagnetic Radiation Detectors to detect noise to eliminate radio interference. The chip is imported from Germany.

The ABS Sensors’ sole function is to measure the rotational speed of a wheel and then transmit the collected information to the vehicle’s Engine Control Module (ECM) to assist the anti-lock braking system in controlling the cars driving stability under varying conditions. With premium wire casings, excellent electrical conductivity, and rigorous testing, we can ensure the high performance, durability, and longevity you expect for your vehicle.

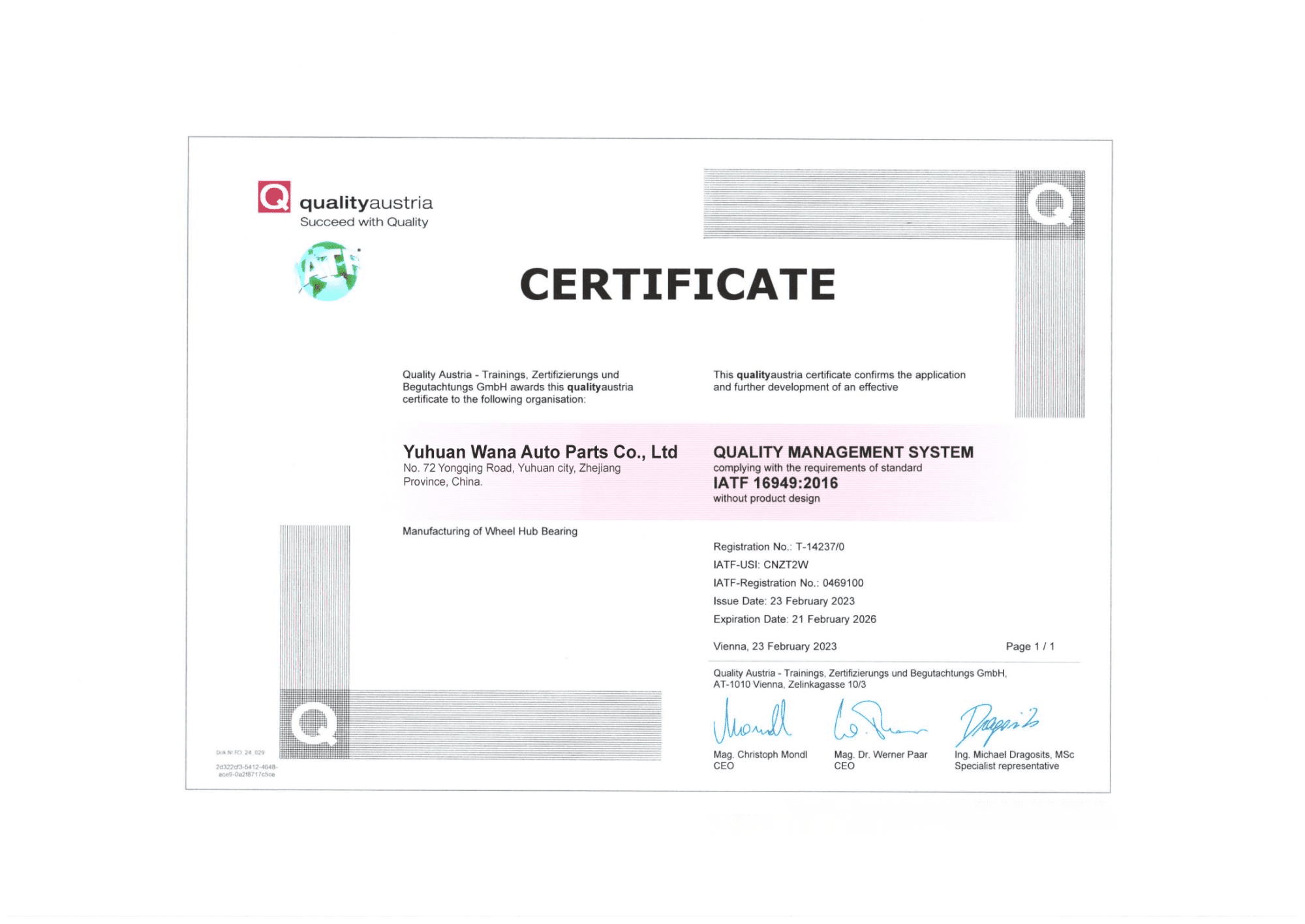

Our Certificate

IATF 16949:2016

Please see our IATF 16949:2016 certificate, which is another reflection of our strength; after all, not all wheel hub factories have the ability to obtain this certificate.

Our Awesome Customers

What Our Lovely Customers Says

Over the years, we have served over 200 foreign and over 150 domestic clients, and our products’ quality, service quality, and response speed have given a very high evaluation and praise rate of more than 99%! Here’s what they all have to say about us.

FAQ About Our Wheel Bearing And HUb Assembly

These are the most frequently asked questions. If you cannot find an answer here, please get in touch with us via email.

We are a family business manufacturing located in Yuhuan city, China’s largest automotive chassis parts zone. There are tens of thousands of factories of automotive chassis parts here. So you can find any chassis parts here.

Usually, the minimum order quantity is 200 pcs, because some models we have in stock, and for those we don’t have in stock, the minimum order quantity is 400 pcs.

We offer EXW, FOB, CFR, CIF, and Door to Door delivery terms. All subject to customer requirements.

Accurate factory price, no middle man.

Yes, we offer free samples for your test.

All products from Wana Auto Parts are covered with a 24 Months warranty from the date of installation or 80,000 km, whichever comes earlier.

- Check whether the product pictures are consistent.

- Also, verify that the product OE or standard primary manufacturer number is correct.

- Then, check if the applicable model and year are accurate.

- Finally, check if the product length and mounting dimensions are correct.

Any port in China is ok for us, but the most are Ningbo, Shanghai, Yiwu, Guangzhou, Qingdao etc.

- Pay 30% in advance and 70% before shipment by T.T.

- 100% payment before shipment by T.T.

- 100% payment aginst BL copy by T.T.

- 100% payment 30 days from shipping date by T.T.

Usually, for the models we have, the lead time will be less than 80 days; for newly developed products, the lead time will be 95 days.

All shipment products are documented, and we provide OEM services to many brands without any information about our manufacturer of the goods. Any drawings, operating instructions, test reports, etc., belong to the brand owner.

Yes, custom service is our leading service, tell us your requirements, and we’ll take care of the rest.

Yes, anything you need.

- Provide samples, and we will make drawings, or you can provide us with detailed production drawings.

- Then, make a mold and produce a few roughs.

- Produce pre-production samples and send them to you for confirmation.

- After your side approves the samples, we will start mass production.

- If you do not confirm the sample, we will make changes according to your requirements and resend the sample to you until you approve the sample.

- After the mass production, you can arrange for a third party to inspect the goods, or we will send you samples of large goods for your inspection.

- After you approve, we will ship your goods.

Who paid for the mold, and who owns the mold.