Introduction:

Noise, Vibration, and Harshness (NVH) performance is critical to automotive engineering, impacting the overall driving experience and vehicle quality.

Wheel hub assemblies and bearings play a significant role in determining NVH performance, as they directly affect the rotational smoothness and stability of the wheels.

In this article, we will explore the various factors related to wheel hub assemblies and bearings that influence NVH performance and discuss ways to optimize these components for a more comfortable and quieter ride.

Wheel Hub Assemblies and Their Role in NVH Performance

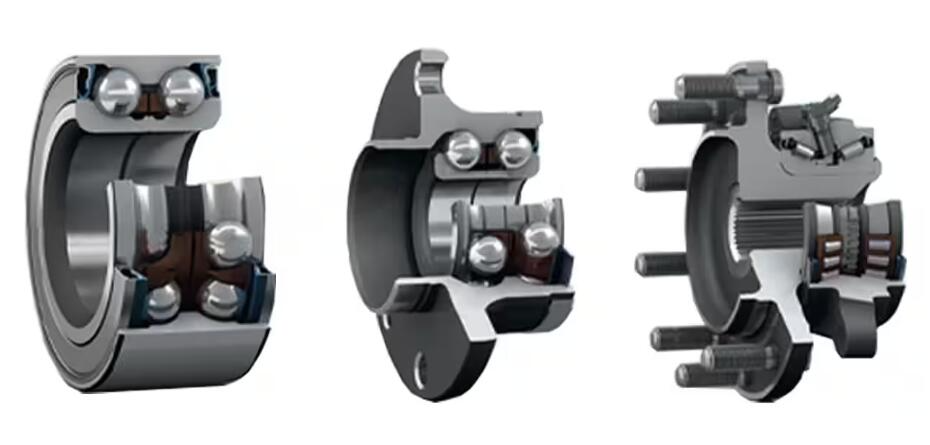

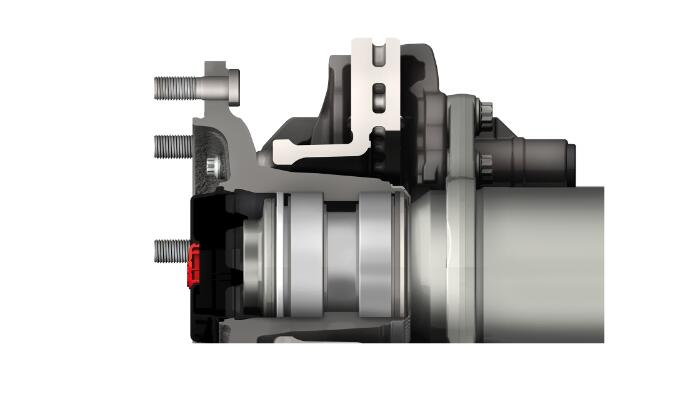

Wheel hub assemblies are the key components that connect the wheels to the vehicle’s suspension and steering systems.

They have several components, including the wheel hub, bearings, and mounting hardware.

These assemblies directly affect NVH performance, maintaining smooth and stable wheel rotation while transmitting loads between the wheel and suspension components.

A properly designed and manufactured wheel hub assembly ensures that the wheels rotate smoothly and with minimal vibration, reducing noise and harshness levels inside the cabin.

However, if the wheel hub assembly is of low quality or becomes damaged, it can generate increased vibrations and noise levels, negatively impacting NVH performance.

Some factors related to wheel hub assemblies that can influence NVH performance include:

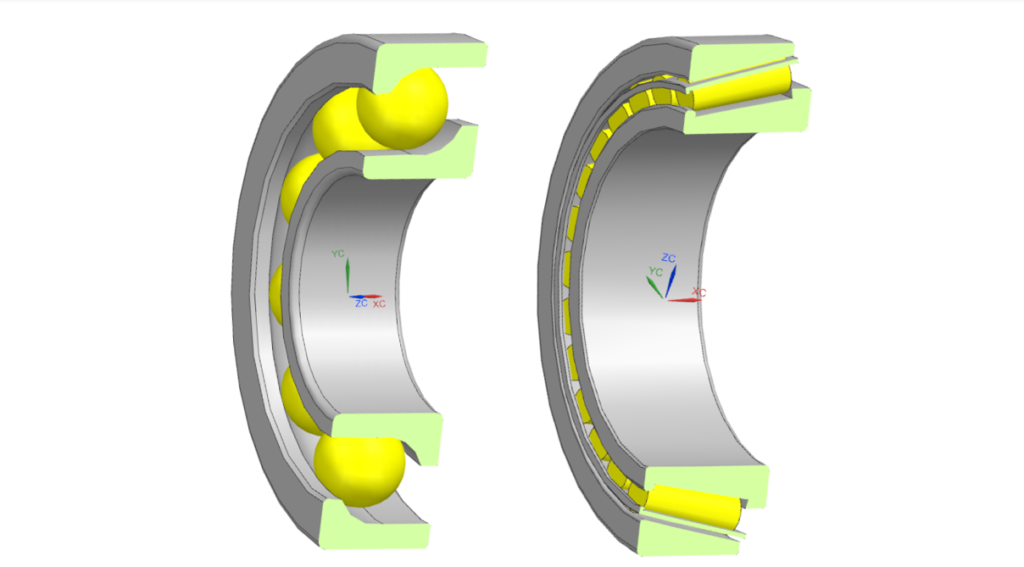

- Bearing type and design: The choice of bearing type (such as a ball or tapered roller bearings) and design can significantly impact NVH performance.

Bearings with optimized designs and high-quality materials can help reduce vibrations and noise levels.

- Hub and bearing preload: Proper preload in the wheel hub assembly is essential for maintaining optimal NVH performance.

Insufficient or excessive preload can increase vibrations, noise, and premature component wear.

- Manufacturing quality: High-quality manufacturing processes and materials ensure a durable and reliable wheel hub assembly.

Poor manufacturing quality can lead to component failures or increased NVH issues.

Wheel Bearings and Their Impact on NVH Performance

Wheel bearings are critical components within the wheel hub assembly that facilitate smooth wheel rotation and support the vehicle’s weight.

These bearings directly impact NVH performance, as they influence the smoothness and stability of wheel rotation.

High-quality wheel bearings can significantly reduce noise, vibration, and harshness levels.

They achieve this by providing low friction, smooth operation, and precise alignment between the wheel hub and suspension components.

Conversely, low-quality or worn wheel bearings can increase vibration and noise levels, decreasing NVH performance.

Factors related to wheel bearings that can impact NVH performance include:

- Bearing type and design: As mentioned earlier, the choice of bearing type and design can significantly impact NVH performance.

Bearings with optimized designs and high-quality materials can help reduce vibrations and noise levels.

- Lubrication: Proper lubrication of the wheel bearings is essential for minimizing friction and ensuring smooth operation.

Insufficient or contaminated lubrication can result in increased noise and vibration levels.

- Bearing wear and damage: Wheel bearings can experience wear or damage over time, increasing noise and vibration levels.

Regular inspection and wheel bearings maintenance is crucial for optimal NVH performance.

The Effects of Wheel Hub Assembly and Bearing Failure on NVH Performance

Wheel hub assembly and bearing failures can significantly impact NVH performance.

When these components fail, they can cause increased vibration and noise levels, leading to a decline in vehicle comfort and ride quality.

Some common signs of wheel hub assembly and bearing failure include:

- Abnormal noise: Damaged or worn wheel bearings can generate abnormal noises, such as grinding or growling, which can be heard outside the vehicle or inside the cabin.

These noises often worsen with increased vehicle speed or when turning.

- Excessive vibration: Wheel hub assembly or bearing failures can cause excessive vibration in the steering and suspension systems.

This vibration can be felt through the steering wheel and may be more pronounced at certain speeds.

- Steering problems: Damaged wheel hub assemblies or bearings can negatively impact steering performance, causing issues such as steering wander or difficulty turning the wheel.

This can compromise vehicle handling and safety.

- Uneven tire wear: Wheel hub assembly and bearing failures can lead to uneven tire wear due to misalignment or imbalance.

This can further exacerbate NVH issues and reduce tire life.

Addressing wheel hub assembly and bearing failures is crucial for maintaining optimal NVH performance.

Regular inspections and timely replacement of worn or damaged components can prevent these issues and ensure a comfortable, quiet ride.

The Importance of Proper Installation and Maintenance for NVH Performance

Proper installation and maintenance of wheel hub assemblies and bearings are essential for optimal NVH performance.

Incorrect installation or neglected maintenance can increase noise, vibration, and harshness levels, reducing vehicle comfort and ride quality.

Some important aspects of wheel hub assembly and bearing installation and maintenance include:

- Proper torque and preload: Ensuring the correct torque and preload during installation is crucial for maintaining optimal NVH performance.

Insufficient or excessive preload can increase vibrations, noise, and premature component wear.

- Lubrication: Regular lubrication of serviceable wheel bearings is necessary for minimizing friction and ensuring smooth operation.

Sealed bearings come pre-lubricated from the factory and generally do not require additional lubrication.

- Inspection: Regularly inspecting wheel hub assemblies and bearings for signs of wear or damage can help identify potential NVH issues before they become severe.

This includes checking for abnormal noises, excessive play, or signs of heat damage.

- Replacement: Replacing worn or damaged wheel hub assemblies and bearings on time is essential for maintaining optimal NVH performance.

Using high-quality replacement components can help ensure a comfortable, quiet ride.

Material Innovations and Their Impact on NVH Performance

Advancements in materials science and engineering have led to the development of new materials and technologies that can improve NVH performance in wheel hub assemblies and bearings.

Some material innovations that can impact NVH performance include:

- Lightweight materials: Using lightweight materials, such as aluminum or advanced composites, can reduce the overall weight of the wheel hub assembly, potentially leading to reduced noise and vibration levels.

- Advanced bearing materials: New materials, such as ceramic or low-friction coatings, can help reduce friction and wear in wheel bearings, improving NVH performance.

- Noise-damping materials: Incorporating noise-damping materials, such as rubber or elastomeric compounds, within the wheel hub assembly can help isolate and reduce noise and vibration transmission to the vehicle’s chassis.

These material innovations have the potential to significantly improve NVH performance in wheel hub assemblies and bearings, contributing to a more comfortable and quieter driving experience.

The Role of Design and Engineering in NVH Performance

Design and engineering are critical in determining the NVH performance of wheel hub assemblies and bearings.

Engineers must carefully consider various factors, such as material selection, geometric design, and manufacturing processes, to optimize NVH performance.

Some design and engineering considerations that can impact NVH performance include:

- Bearing design: As previously mentioned, the bearing type and design choice can significantly impact NVH performance.

Engineers must carefully select bearing designs that minimize friction, vibration, and noise.

- Hub geometry: The geometry of the wheel hub can influence NVH performance by affecting the assembly’s stiffness, mass, and vibration characteristics.

Optimizing hub geometry can help reduce vibrations and noise transmission to the vehicle’s chassis.

- Manufacturing tolerances: Tight manufacturing tolerances are crucial for ensuring precise alignment and fitment of wheel hub assembly components.

Poor manufacturing tolerances can increase vibrations and noise levels, negatively impacting NVH performance.

- Structural optimization: Engineers can use computational tools, such as finite element analysis (FEA), to optimize the structural design of wheel hub assemblies and bearings for reduced noise, vibration, and harshness levels.

By carefully considering these design and engineering factors, it is possible to develop wheel hub assemblies and bearings that provide excellent NVH performance, contributing to a comfortable and quiet driving experience.

Testing and Validation of NVH Performance

Testing and validation are crucial for ensuring the NVH performance of wheel hub assemblies and bearings.

Various testing methods can be employed to measure and evaluate the noise, vibration, and harshness levels generated by these components. Some common testing methods include:

- Vibration testing involves subjecting wheel hub assemblies and bearings to controlled vibrations to measure their response and identify potential NVH issues.

- Acoustic testing: Acoustic testing involves measuring the noise generated by wheel hub assemblies and bearings under various operating conditions.

This can help engineers identify and address noise-related NVH issues.

- Road testing involves evaluating the NVH performance of wheel hub assemblies and bearings on a test vehicle under real-world driving conditions.

This provides valuable insights into the overall NVH performance of the components and allows for adjustments as needed.

By conducting thorough testing and validation, engineers can ensure that wheel hub assemblies and bearings meet the desired NVH performance targets, leading to a more comfortable and quieter driving experience.

The Future of Wheel Hub Assemblies and Bearings for Improved NVH Performance

The automotive industry continues to evolve, and ongoing research and development efforts aim to improve the NVH performance of wheel hub assemblies and bearings.

Some potential future developments in this area include:

- Advanced materials: The development and implementation of new materials with superior properties, such as reduced weight, improved noise damping, or lower friction, could lead to significant improvements in NVH performance.

- Active noise and vibration control: Active noise and vibration control technologies, such as piezoelectric or electromagnetic actuators, could be integrated into wheel hub assemblies and bearings to counteract noise and vibration levels actively, further improving NVH performance.

- Integrated sensors: Incorporating sensors into wheel hub assemblies and bearings could enable real-time monitoring of NVH performance and facilitate predictive maintenance, helping to maintain optimal NVH performance throughout the life of the components.

- Advanced manufacturing techniques: Adopting advanced manufacturing techniques, such as additive manufacturing or precision machining, could produce wheel hub assemblies and bearings with tighter tolerances and more complex geometries, improving NVH performance.

As the automotive industry continues to innovate, the future of wheel hub assemblies and bearings promises further improvements in NVH performance, contributing to a more comfortable and enjoyable driving experience for motorists.

The Importance of Proper Wheel Alignment for NVH Performance

Proper wheel alignment is crucial in maintaining optimal NVH performance in vehicles.

Misaligned wheels can increase noise, vibration, and harshness levels by causing uneven tire wear, steering issues, and excessive vibrations in the suspension system.

Some key aspects of wheel alignment and their impact on NVH performance include:

- Camber, caster, and toe: These primary alignment angles directly affect tire wear and vehicle handling.

Incorrect camber, caster, or toe settings can cause excessive tire wear and negatively impact NVH performance by generating increased road noise, vibration, and harshness.

- Suspension components: Worn or damaged suspension components, such as bushings, ball joints, and control arms, can cause wheel misalignment and contribute to NVH issues.

Regular inspection and replacement of these components are essential for maintaining proper wheel alignment and optimal NVH performance.

- Tire balance and pressure: Unbalanced tires or incorrect tire pressure can also contribute to NVH issues by causing vibrations that can be felt through the steering wheel, floor, and seats.

Properly balanced tires and maintaining the recommended tire pressure are essential for optimal NVH performance.

Regular wheel alignment checks and adjustments are necessary to maintain optimal NVH vehicle performance.

Vehicle owners can ensure a more comfortable and quieter driving experience by addressing misalignment issues.

Impact of Road Conditions on NVH Performance

Road conditions can significantly impact the NVH performance of wheel hub assemblies and bearings.

Rough, uneven, or damaged road surfaces can introduce additional noise and vibrations, negatively affecting the overall NVH performance of a vehicle.

Some factors related to road conditions that can impact NVH performance include:

- Road surface irregularities: Potholes, cracks, and other surface irregularities can cause increased vibrations and noise levels in the wheel hub assembly and bearings, reducing NVH performance.

- Road texture: The texture of the road surface can also influence NVH performance.

Rough, coarse textures can generate more tire noise and vibrations than smooth surfaces, affecting the overall NVH performance of the vehicle.

- Road gradients and curves: Steep road gradients and tight curves can place additional stress on wheel hub assemblies and bearings, potentially causing increased noise and vibration levels.

To minimize the impact of road conditions on NVH performance, vehicle manufacturers and engineers must carefully consider factors such as suspension design, tire selection, and wheel hub assembly and bearing design.

Additionally, regular maintenance and proper installation of these components can help ensure optimal NVH performance, even in challenging road conditions.

The Role of Aftermarket Components in NVH Performance

The use of aftermarket components can significantly impact the NVH performance of wheel hub assemblies and bearings.

Aftermarket components may offer improved performance, reduced weight, or enhanced durability compared to original equipment manufacturer (OEM) parts.

However, not all aftermarket components are equal; some may negatively impact NVH performance.

When considering aftermarket components for wheel hub assemblies and bearings, it is essential to:

- Evaluate the quality: High-quality aftermarket components produced by reputable manufacturers should meet or exceed OEM specifications.

These components are more likely to maintain or improve NVH performance than lower-quality alternatives.

- Research the manufacturer: Choose aftermarket components from reputable manufacturers with a proven track record in the industry.

This can help ensure the components are high quality and will not negatively impact NVH performance.

- Consider compatibility: Ensure that the selected aftermarket components are compatible with the vehicle’s make, model, and other components in the wheel hub assembly and bearing system.

Incompatible components can lead to increased vibrations, noise, and premature wear.

By carefully selecting aftermarket components for wheel hub assemblies and bearings, vehicle owners can maintain or even improve the NVH performance of their vehicles.

Researching and choosing high-quality components from reputable manufacturers is essential to ensure optimal compatibility and performance.

Impact of Proper Maintenance on NVH Performance

Proper maintenance is crucial for optimal NVH performance in wheel hub assemblies and bearings.

Regular maintenance checks and timely replacement of worn or damaged components can significantly impact the overall noise, vibration, and harshness levels experienced by vehicle occupants.

Some essential maintenance practices for ensuring optimal NVH performance include:

- Regular inspection: Inspect wheel hub assemblies and bearings for signs of wear or damage at regular intervals, as the vehicle manufacturer recommends.

This can help identify potential issues before they lead to significant NVH problems.

- Lubrication: Proper lubrication of wheel bearings is essential for reducing friction and preventing premature wear.

Ensure the bearings are adequately lubricated according to the manufacturer’s recommendations to maintain optimal NVH performance.

- Component replacement: Replace worn or damaged components, such as bearings, seals, and suspension parts, to maintain proper wheel alignment, balance, and overall NVH performance.

- Tire maintenance: Regularly check tire pressure, alignment, and balance to ensure optimal contact with the road and minimize vibrations and noise.

By following these maintenance practices, vehicle owners can help maintain the NVH performance of their wheel hub assemblies and bearings, contributing to a more comfortable and quiet driving experience.

Conclusion:

In conclusion, wheel hub assemblies and bearings play a critical role in determining the overall NVH performance of a vehicle.

Numerous factors, such as design, material selection, engineering, road conditions, aftermarket components, and maintenance, can impact the noise, vibration, and harshness levels experienced by vehicle occupants.

By carefully considering these factors and implementing best practices, optimizing wheel hub assemblies and bearings for improved NVH performance is possible, contributing to a more comfortable and enjoyable driving experience.

As the automotive industry continues to innovate and evolve, ongoing research and development efforts promise to enhance further the NVH performance of wheel hub assemblies and bearings, ultimately benefiting motorists worldwide.