Introduction:

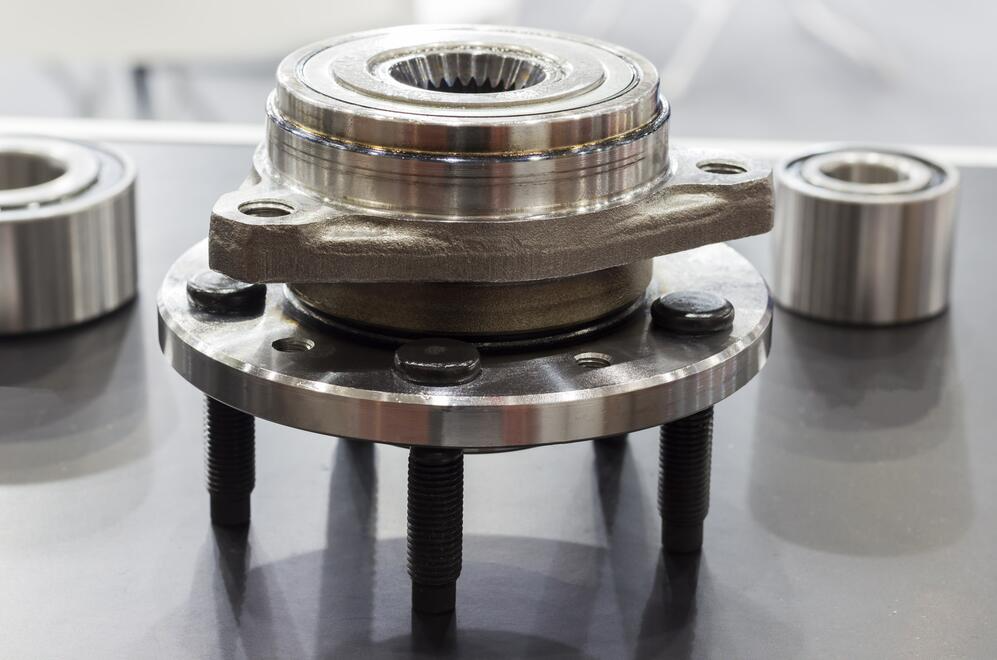

As a wholesale or retail business owner in the automotive industry, you must ensure the quality of wheel hub and bearing assemblies you supply to your customers.

High-quality wheel hubs and bearings contribute to vehicle safety, performance, and longevity.

This article will provide an in-depth guide on evaluating wheel hub and bearing assembly quality, so you can confidently provide your customers with top-notch products.

Material Quality

Material quality is a vital aspect to consider when evaluating wheel hubs and bearing assemblies.

The materials used in manufacturing directly impact the product’s durability, performance, and longevity.

High-quality wheel hubs and bearings are typically made from premium materials, such as high-grade steel, aluminum, or other alloys.

These offer superior strength, resistance to wear and corrosion, and excellent heat dissipation properties.

To evaluate material quality, look for information from the manufacturer regarding the materials used in their products.

Additionally, inquire about certifications or standards followed during material selection and manufacturing processes, such as ISO or ASTM standards.

You may also want to ask about the material’s composition and any special treatments, such as heat treatment, used to enhance its properties.

Investing in high-quality materials ultimately leads to a more reliable and longer-lasting product, ensuring customer satisfaction and brand reputation.

When evaluating the material quality of wheel hubs and bearing assemblies, it’s essential to consider the primary materials used for the components and the auxiliary materials, such as lubricants and coatings.

High-quality wheel hubs and bearing assemblies may utilize advanced lubricants that perform better under various operating conditions, such as extreme temperatures or harsh environments.

Additionally, advanced surface treatments and coatings can enhance the durability and corrosion resistance of wheel hub and bearing components, extending their service life and reducing maintenance requirements.

Manufacturing Processes and Tolerances

The manufacturing processes and tolerances maintained during the production of the wheel hub and bearing assemblies are crucial factors in determining their quality.

High-precision manufacturing techniques, such as CNC machining, grinding, and heat treatment, are essential in achieving tight tolerances and ensuring the final product’s fit, form, and function.

Advanced manufacturing technologies like robotic automation can improve quality and consistency.

To evaluate manufacturing processes and tolerances, look for information on the production techniques used by the manufacturer.

Additionally, consider the quality control measures employed during manufacturing, such as inspections, testing, and certifications.

Manufacturers adhering to industry standards like ISO/TS 16949 or IATF 16949 are more likely to produce high-quality wheel hubs and bearing assemblies.

Furthermore, consider visiting the manufacturing facility to see the production processes and quality control measures firsthand.

Performance Specifications

Evaluating the performance specifications of wheel hubs and bearing assemblies is crucial to ensure they meet or exceed the requirements of your customers’ vehicles.

Key performance metrics include load-carrying capacity, rotational speed, and service life.

High-quality wheel hub and bearing assemblies will typically offer better performance across these parameters, improving vehicle handling, fuel efficiency, and overall reliability.

To assess performance specifications, compare the products’ technical data sheets and performance metrics provided by the manufacturer.

It is essential to ensure the wheel hub and bearing assemblies you supply meet or exceed the original equipment manufacturer (OEM) specifications for the specific vehicle applications they are intended for.

Additionally, consider any innovations or technological advancements the manufacturer has incorporated into their products to improve performance, such as optimized bearing designs, advanced materials, or specialized lubrication systems.

Performance specifications vary significantly between the wheel hub and bearing assemblies, even within the same product category.

Understanding the specific performance requirements of the vehicles or applications you intend to offer these products is crucial. Consider load capacity, rotational speed, and service life factors when evaluating performance specifications.

High-quality wheel hub and bearing assemblies will typically exhibit superior performance characteristics in these areas, ensuring optimal vehicle performance and safety.

Additionally, some manufacturers may provide detailed performance data or test results to help you compare and evaluate different products more effectively.

Lubrication and Sealing

Proper lubrication and sealing are critical to the longevity and performance of wheel hubs and bearing assemblies.

High-quality assemblies will typically feature well-designed sealing systems that prevent the ingress of contaminants and moisture while retaining lubricants.

This ensures that the bearings remain adequately lubricated, reducing friction, wear, and the risk of premature failure.

When evaluating lubrication and sealing, look for information on the type of lubricants used and the sealing system employed in the wheel hub and bearing assembly.

High-quality products often use synthetic or long-life lubricants, providing better performance over a wide temperature range and extended service life.

Additionally, consider the design and materials of the sealing system, such as high-performance elastomers or advanced sealing geometries, which can contribute to improved sealing performance and durability.

NVH Performance

Noise, vibration, and harshness (NVH) performance is a critical aspect of the wheel hub and bearing assemblies, as it directly impacts the overall driving experience and comfort of the vehicle.

High-quality wheel hub and bearing assemblies will typically offer superior NVH performance by reducing noise and vibration levels generated during operation.

This can be achieved through optimized bearing designs, advanced materials, and precise manufacturing techniques.

When evaluating NVH performance, rely on the noise, vibration, and harshness levels provided by the manufacturer.

Some manufacturers may provide specific NVH performance metrics like decibel ratings or vibration measurements.

Additionally, check for advanced design features, such as optimized bearing geometries or enhanced sealing systems, which can improve NVH performance.

Reviewing customer feedback or third-party test results related to the product’s NVH performance is also helpful.

Aftermarket Support and Warranty

Aftermarket support and warranty policies are essential when evaluating the quality of wheel hubs and bearing assembly.

High-quality products are often backed by a strong warranty policy, reflecting the manufacturer’s confidence in the durability and reliability of their products.

In addition, manufacturers that offer comprehensive aftermarket support can provide valuable resources, such as technical assistance, product training, and replacement parts, ensuring the best possible experience for your customers.

To evaluate aftermarket support and warranty, look for the manufacturer’s warranty policy information, including coverage duration and terms.

Additionally, consider the level of aftermarket support the manufacturer provides, such as customer service, technical assistance, and the availability of replacement parts.

Choosing products from manufacturers with strong aftermarket support and warranty policies can help you build trust with your customers and strengthen your brand reputation.

Third-Party Certifications and Testing

Third-party certifications and testing can provide valuable insights into wheel hubs’ quality and bearing assemblies’ quality.

Independent organizations and testing facilities can objectively evaluate the products’ performance, durability, and compliance with industry standards.

High-quality wheel hubs and bearing assemblies often hold certifications from reputable organizations, such as SAE International, TÜV, or ISO.

To evaluate third-party certifications and testing, look for information on the certifications held by the wheel hub and bearing assemblies or the manufacturer.

Additionally, consider any independent testing performed on the products, such as performance, durability, or environmental testing.

Choosing products that have undergone rigorous third-party evaluation can provide more confidence in their quality and reliability.

In addition to the previously mentioned third-party certifications, such as SAE International, TÜV, or ISO, other industry-specific certifications may be relevant when evaluating wheel hub and bearing assemblies.

These certifications can include IATF 16949 (International Automotive Task Force) certification, which demonstrates compliance with stringent quality management system requirements for automotive suppliers.

Furthermore, some manufacturers may also participate in voluntary quality assurance programs, such as the Bearing Specialists Association’s (BSA) Certified Bearing Specialist program, which can provide additional confidence in the quality of their products.

Customer Reviews and Testimonials

Customer reviews and testimonials can offer valuable insights into the real-world performance and quality of wheel hubs and bearing assemblies.

By considering the experiences of other wholesale or retail businesses and end-users, you can better understand the product’s strengths and weaknesses and make a more informed decision when selecting your suppliers.

To evaluate customer reviews and testimonials, look for feedback from other businesses or end-users who have used the wheel hub and bearing assemblies.

Consider both positive and negative feedback and any common themes or issues that may arise.

Remember that customer satisfaction is a critical aspect of your business’s success. Selecting high-quality wheel hubs and bearing assemblies can help ensure customers are satisfied with their purchases.

Conclusion:

Evaluating wheel hub and bearing assembly quality is essential for your wholesale or retail business to provide top-notch products to your customers.

You can confidently select high-quality wheel hubs and bearings by considering material quality, manufacturing processes, performance specifications, lubrication and sealing, NVH performance, aftermarket support and warranty, third-party certifications, and customer reviews assemblies that will meet or exceed your customers’ expectations.

Investing in high-quality wheel hubs and bearing assemblies will contribute to better vehicle performance and safety and also help enhance your brand reputation, customer satisfaction, and, ultimately, your business’s success.

By carefully considering these factors and conducting thorough research on the products and manufacturers you choose to work with, you will be well-equipped to make informed decisions when selecting wheel hub and bearing assemblies for your wholesale or retail business.

Remember that the quality of the products you offer will directly impact your customers’ experiences and the overall success of your business.

As the automotive industry continues to evolve and innovate, staying informed about the latest advancements in wheel hub and bearing assembly technology and industry best practices will be crucial to maintaining a competitive edge in the market.

By staying up-to-date on industry trends and constantly striving to improve the quality of the products you offer, you will be well-positioned to meet the demands of your customers and grow your business in the ever-changing automotive landscape.

In conclusion, prioritizing quality in your wheel hub and bearing assemblies is essential for the success of your wholesale or retail business.

By thoroughly evaluating the various factors discussed in this article and selecting products that meet or exceed your customers’ expectations, you can ensure that your business thrives and maintains a strong reputation in the competitive automotive industry.

Happy customers are the key to a successful business, and providing high-quality wheel hubs and bearing assemblies is a critical step in achieving that goal.