Trusted by dozens of world-class brands and organizations of all sizes

Who We Are

The Only Factory in China Specializing in Russian Cars and Truck Parts

Wana Auto Parts Co., Ltd owned this site wheelhubfactory.com. We manufacture high-performance wheel bearings and hub assemblies. Our factory is located in Yuhuan City, the biggest auto chassis parts production base in China, and all the products are under strict quality control before delivery. Our experienced technicians are always ready to provide the necessary services for you.

We're Specialist on Russian cars and Trucks

- Over 2800 models in range

- $20 million annual output

- Capacity 10,000 sets per day

Our Advantages

From Roughs to Assemblies Are All Made by Us

Extreme cost control, strict quality control, rich market experience, and good communication are incomparable to any factory.

2 years or 80,000 km warranty.

Russian Cars and Trucks Spare Parts

All Russian vehicles here include UAZ, GAZ, LADA, KAMAZ, etc. We will continue to develop new products; anything you can’t find elsewhere, we can develop for you, and we bear all the development costs ourselves.

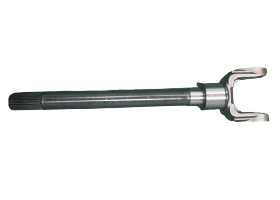

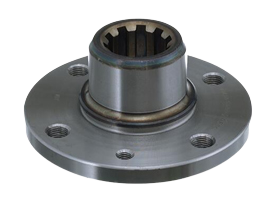

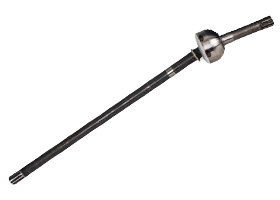

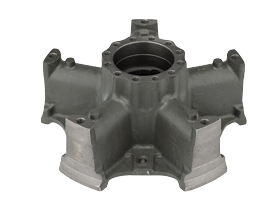

Flange GAZ-33027 transfer case TRANSFER CASE FLANGE SOBOL 4X4 CV JOINT 33027-1802044-10 factory

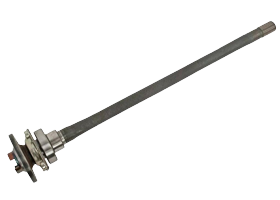

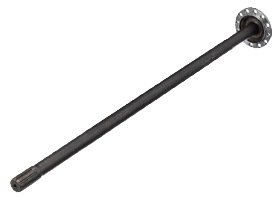

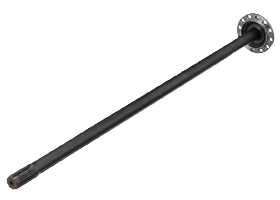

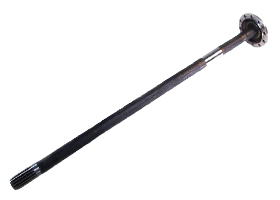

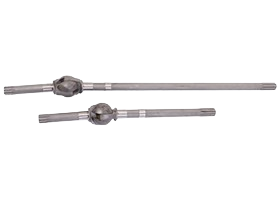

Rear axle drive flange RK Dymos / UAZ Patriot, Pickup (DYMOS / Korea) 3163-80-1802076 factory

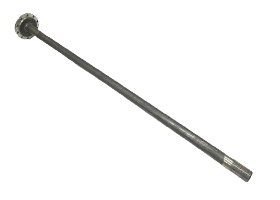

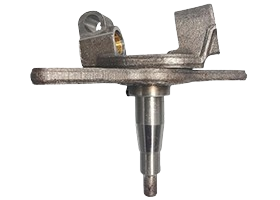

GAZ-33027 axle for steering knuckle STEERING KNUCKLE AXLE GAZELLE 4X4 33027-2304080 factory

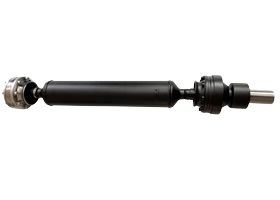

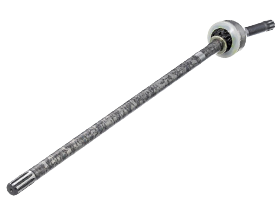

Shaft UAZ-3163 Patriot (RK DYMOS) front axle transfer case 48281T00015 31638-1802110 factory

GAZ-33027 fork of the steering knuckle joint, internal right, long 33027-2304064-01 factory

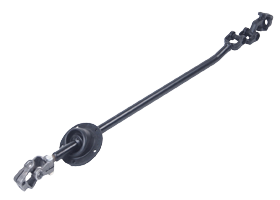

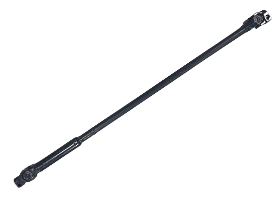

UAZ-3163 steering cardan shaft assembly for power steering Delphi 3163-3401400-40 factory

UAZ-3163 (14-) steering cardan shaft assembly for power steering YB 316310-3401400-00 factory

Steering cardan shaft GAZon NEXT assembly shaft cardan steering Lawn next C41R11-3401042 factory

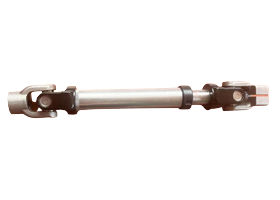

Cardan shaft GAZelle-33027 Business all-wheel drive front rear with CV joint 8 bolts 5022382-2 factory

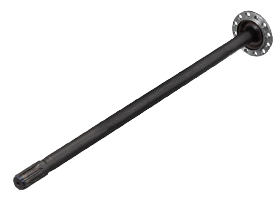

UAZ-469 flange for the propeller shaft of the front and rear gear axles 469-2402100 factory

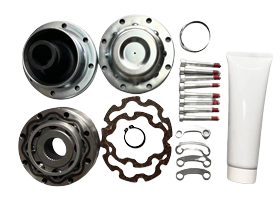

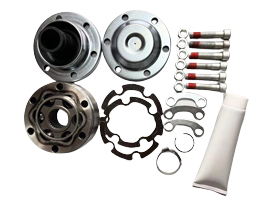

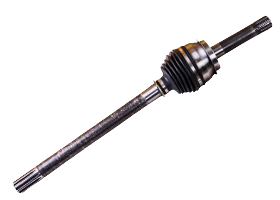

CV joint of the steering knuckle UAZ-452 UAZ-469 reinforced right short 31512-2304060 factory

Steering knuckle joint UAZ-315195 UAZ-3741 cv joint Spicer bridge Hybrid left 31605-2304061 factory

CV joint of the steering knuckle left UAZ-3163 Patriot 236022 Pro 4×4 236022-2304060 factory

CV joint of the steering knuckle right UAZ-3163 Patriot 236022 Pro 4×4 236022-2304060 factory

PRIMARY SHAFT BEARING COVER GAZ-2705, 3302, GAZELLE NEXT ENGINE CUMMINS 3302-1701040 factory

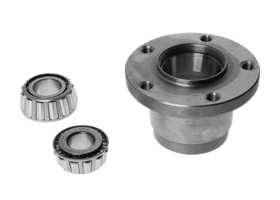

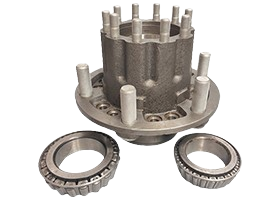

3302-3104008 Hub GAZ-3302, GAZelle NEXT rear, assembled with bearings, without studs factory

31029-1701175-01 Gearbox clutch GAZ-3302, GAZelle Next 1-2, 3-4, 5 and reverse factory

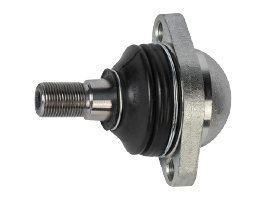

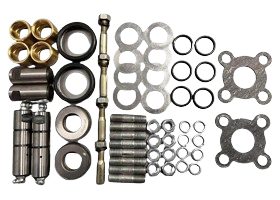

C41RB3-3000100, C40R13-3001019 King Pin assembly for GAZon NEXT 10 t C40R13, PAZ-Vector with axle C41RV3-3000012 factory

33104-3000100, 33104-3000101 Complete kingpin for Valday GAZ-33104 , GAZon NEXT C41R11 with axle C41R11-3000012 factory

32217-1802043 Transfer case flange Gazelle 4×4, Sobol 4×4 CV joint for 6 bolts factory

27057-2402138 Rear/front axle gearbox flange for gazelle 4×4 sable 4×4 for 6 bolts factory

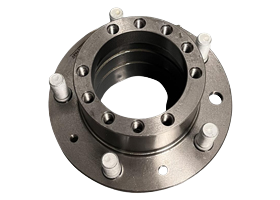

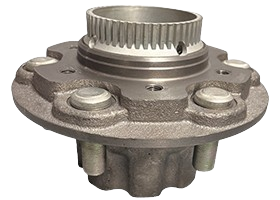

C41R11-3104006-10 GAZon Next rear hub assembly with ABS with bearing with studs factory

33104-3104004 GAZ-3310 Valdai rear hub assembly with ABS with bearing with studs factory

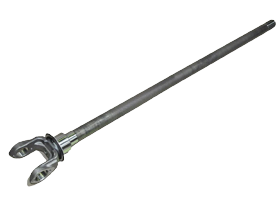

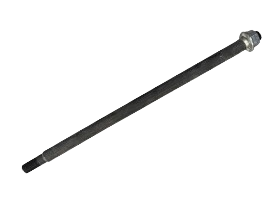

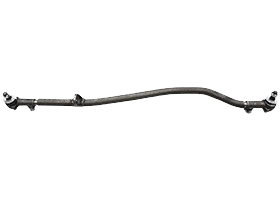

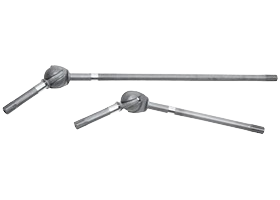

3160-290901021 316000-2909010-21 Rod UAZ-3160, 3163, 315195 longitudinal with hinge assembly factory

53-2402051-B Cover of the front housing of the rear axle for GAZ 53, 66, 3307, 3309 factory

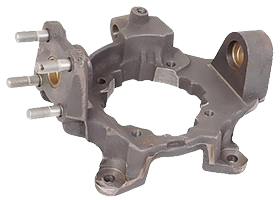

23107-2304041 Left steering knuckle housing GAZ-23107 Sobol 4*4 all-wheel drive factory

23107-2304044 Right steering knuckle housing GAZ-23107 Sobol 4*4 all-wheel drive factory

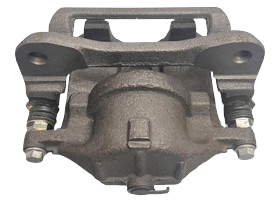

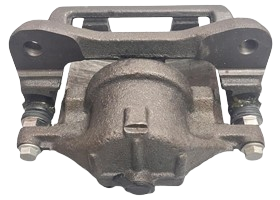

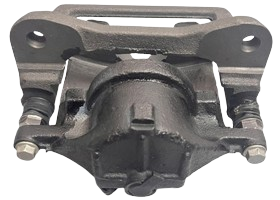

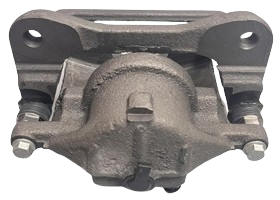

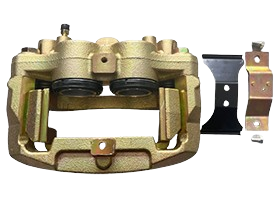

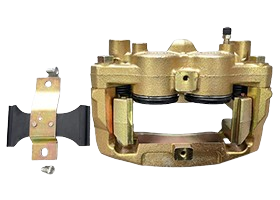

C41R11.3501137 Caliper LAWN NEXT, Groove Vector NEXT left front rear with pads factory

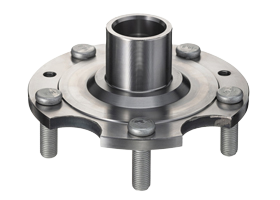

Manufacturer GAZ-2217 front hub with studs with ABS rotor without bearing, 2217-3103004-01

Manufacturer GAZ-2217 front hub with studs without ABS rotor without bearing, 2217-3103004

Manufacturer hub GAZ-3302, GAZelle NEXT rear, assembled with bearings, with studs, 3302-3104008-10

Manufacturer hub GAZ-3302, GAZelle NEXT rear, assembled without bearings, with studs, 3302-3104008-01

Manufacturer hub GAZ-3302, GAZelle NEXT rear, assembled without bearings, without studs, 3302-3104008

Manufacturer GAZon Next rear hub assembly without ABS with bearing with studs, С41R11-3104015-10

Manufacturer GAZon Next rear hub assembly without ABS without bearing with studs, С41R11-3104015-01

Manufacturer GAZon Next rear hub (naked) without ABS without bearing without studs, С41R11-3104015

Manufacturer Gazelle next 4.6t rear hub assembly with studs with bearing with ABS, C41R92-3104006-10

Manufacturer Gazelle next 3.5t rear hub assembly with studs with bearing with ABS, A31R32-3104006-10

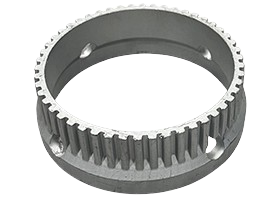

Manufacturer Pulse disc (rotor) rear brake Gazelle Next 4.6t/3.5t ABS, C41R92-3862052-10

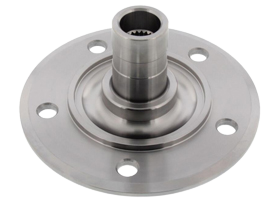

Manufacturer wheel hub UAZ PROFI 236031 POLUTORKA (double-slope axle) front assembly / (since 2021), 236031-3103010

Manufacturer wheel hub UAZ PROFI 236031 POLUTORKA (double axle) REAR assembled, 236031-3104010

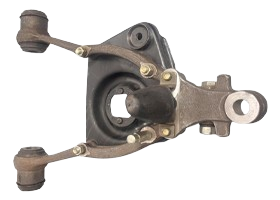

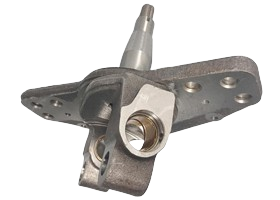

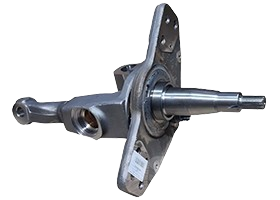

Manufacturer right steering knuckle (for disc brakes) for Gazon Next 10t. (C40RB3, C40R13), Paz Vector Next, C40R13-3001012-10

Manufacturer steering knuckle PAZ Vector NEXT, GAZon NEXT 10t left (disc brakes), C40R13-3001013-10 / C40R13-3001013-11

Manufacturer, housing UAZ-3151, 3741 steering knuckle right (for disc brakes), 3741-00-2304040-95

Manufacturer, housing UAZ-3151, 3741 steering knuckle left (for disc brakes), 3741-00-2304041-95

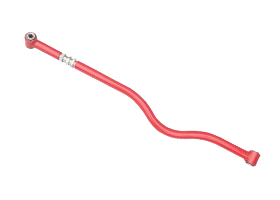

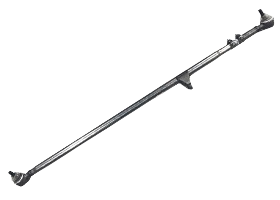

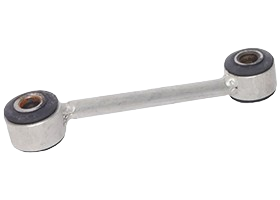

Manufacturer, adjustable transverse rod assembly (Panhard rod) Hunter (red), 3160-00-2909016-01

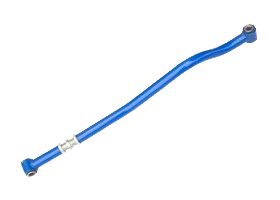

Manufacturer, adjustable transverse rod assembly (Panhard rod) Patriot (blue), 3162-00-2909016-01

Manufacturer, GAZ-3302 rear axle housing (without ABS), 3302-2401005-11 / 3302-2401005-21

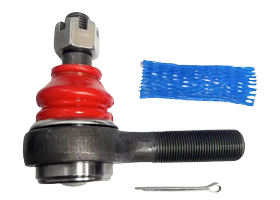

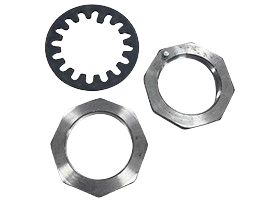

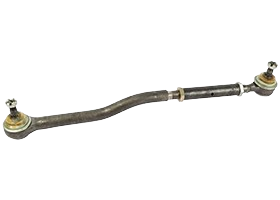

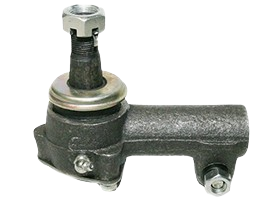

Manufacturer, steering joint assembly for GAZ-3302, 3221, 2217, 2752, 2310 (nut, cotter pin) (set of 4 pcs), 2217-3414029-01

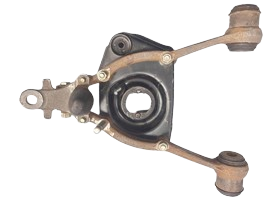

Manufacturer, support UAZ-3163 Patriot left assembled universal (ABS and without pads), 316300-3501011-10

Manufacturer, support UAZ-3163 Patriot right assembled universal (ABS and without pads), 316300-3501010-10

Manufacturer, cushion GAZ-3302 engine CUMMINS, GAZelle Next, GAZon Next engine front left (yellow), 7421018S1, A21R22.1001021-10

Manufacturer, cushion GAZ-3302 engine CUMMINS, GAZelle Next, GAZon Next engine front right (blue), 7421018S3, A21R22.1001020-10

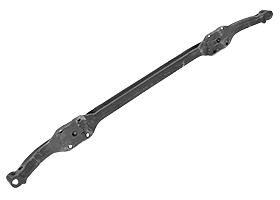

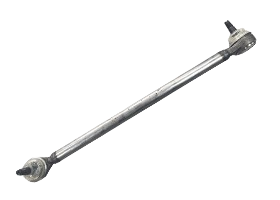

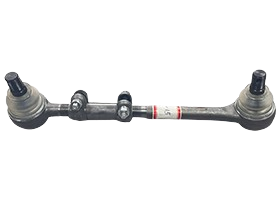

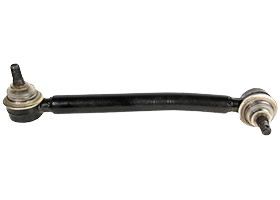

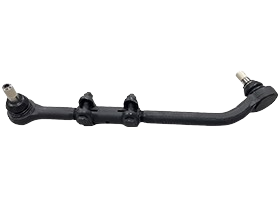

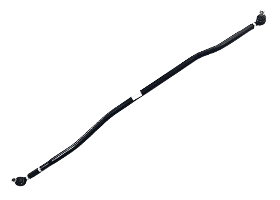

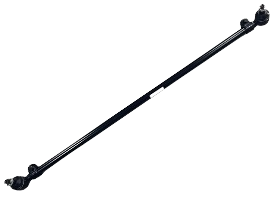

Manufacturer, steering rod GAZ-3310 Valdai, GAZon Next transverse assembly, 33104-3414052-01

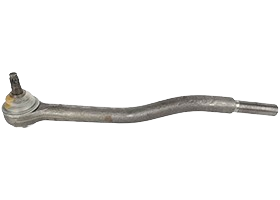

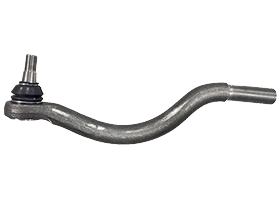

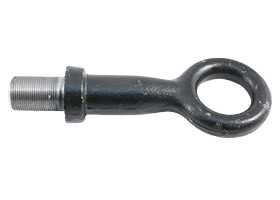

Manufacturer, steering tip for Gazon NEXT 10t front, longitudinal traction, C41RB3-3414013

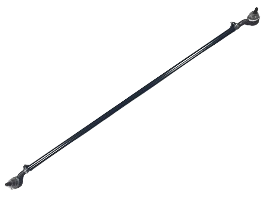

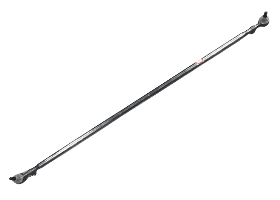

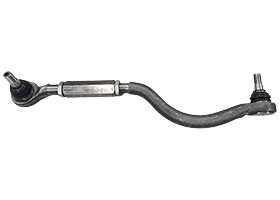

Manufacturer, steering rod UAZ-3163 longitudinal bipod with power steering Delphi, 3163-3414010

Manufacturer, steering knuckle rod UAZ PROFI 236031 “Polutorka” (double-slope bridge), 2360-31-3414010

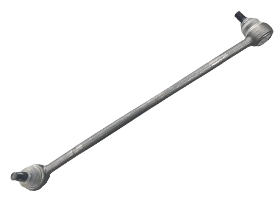

Manufacturer, steering linkage rod (assembled) UAZ Profi (One and a half since 2021), 2360-31-3414052

Manufacturer, steering linkage rod UAZ PATRIOT RESTYLING-2019, PICK-UP (from 09.2018, under steering damper), 3163-3414052

Manufacturer, BIPOD STEERING ROD OF UAZ PATRIOT, PROFI FROM 09.2018 ONWARDS, 2360-3414010

Manufacturer, steering rod for PAZ Vector NEXT, Gazon NEXT vehicles, transverse (long), 10t, C40R13-3414052

Manufacturer, steering tip for Gazon NEXT 10t, PAZ VECTOR left, transverse and longitudinal traction, С40R13-3414057

Manufacturer, steering tip for Gazon NEXT 10t, PAZ VECTOR right, transverse tie rod, C40R13-3414056

Manufacturer, steering rod for a/m GAZ “Sadko NEXT” transverse dv.Yar-53443 Euro-5, C41C23-3414052

Manufacturer, longitudinal traction (steering knuckle) UAZ 452 HYBRID bridge, power steering, 374195-3414010-12

Manufacturer, steering rod UAZ-452 longitudinal Spicer under power steering, 3962-3414010-01

Manufacturer, bipod steering rod UAZ PATRIOT (2005-07), 3162 (L – 914mm), 3162-3414010

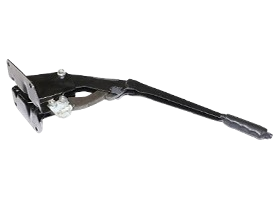

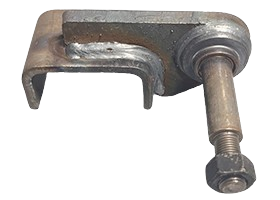

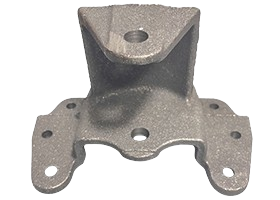

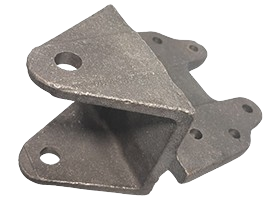

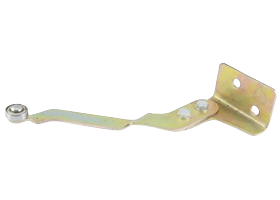

Manufacturer, shock absorber bracket GAZ-3302, GAZelle NEXT rear lower left, А21R23-2915511

Manufacturer, shock absorber bracket GAZ-3302, GAZelle NEXT rear lower right, А21R23-2915510

Manufacturer, spring bracket for additional cushion GAZ-3302, GAZelle NEXT, 3302-2913444

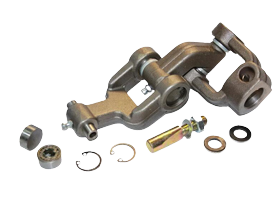

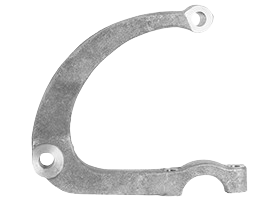

Manufacturer, clutch fork GAZ-3302, GAZelle Next engine CUMMINS ISF 2.8, 3302-1601200-10

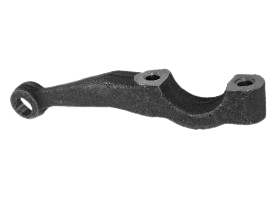

Manufacturer, steering knuckle lever GAZ-3310 Valdai to longitudinal thrust, 33104-3001035

Manufacturer, GAZ-3309 clip, GAZon Next front stabilizer cushion reinforced, C40R13-2906048

Manufacturer, rear stabilizer bushing bracket GAZon NEXT, PAZ Vector NEXT, C40R13-2916048

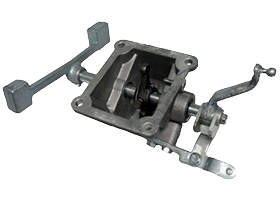

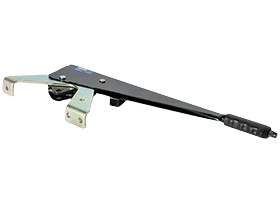

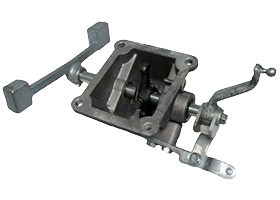

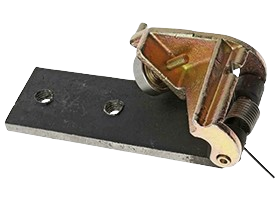

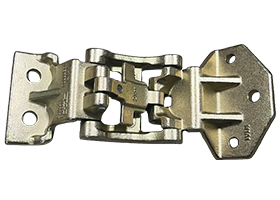

Manufacturer, GAZ-2705 mechanism for opening the door of the middle guide in assembly, 2705-6426150-10

Manufacturer, GAZelle Next mechanism for opening the door of the middle guide in assembly, A31R23.6426150

Manufacturer, Stabilizer bar GAZ-3302, GAZelle Next Business with bracket, bushing, silent block assembly, 3302-2916058

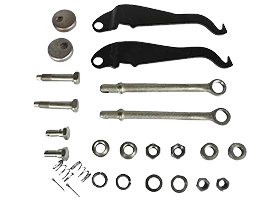

Manufacturer, Steering knuckle joint UAZ 452, 469 new model KIT (left + right) (BALL), 452-2304060/61

Manufacturer, CV joint of steering knuckle UAZ-3741 Hybrid bridge with ground ball (bridge kit), 3741-2304060/61

Manufacturer, rear door hinge for Gazelle Next CMF upper (opening angle 270), A31R23.6306010

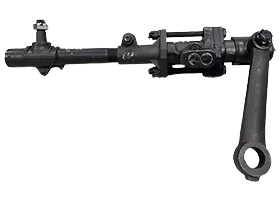

Manufacturer, Steering column UAZ 469 “LUX” SHORT (under power steering), 31512-3401098-21

Manufacturer, steering cardan shaft UAZ 3160, 3162, PATRIOT d20 (for Borisov power steering) 870 mm, 31601-3401400-10

Manufacturer, Steering cardan shaft UAZ 3160, 3162 d23 (for power steering Sterlitamak) 870mm, 31601-3401400

Manufacturer, Steering cardan shaft UAZ 3162, PATRIOT (under ZF power steering) 820 mm, d 17, 31608-3401400

Manufacturer, steering cardan shaft UAZ 452 (Euro-4, for power steering, thin spline) 350mm, 220695-3401400

Manufacturer, steering cardan shaft UAZ 469, HUNTER (for ZF/EXPERT power steering, thin spline) 320mm, 315140-3401400

Manufacturer, steering cardan shaft UAZ 469, HUNTER d23 (for power steering Sterlitamak) 350mm, 31512-3401400-10

Manufacturer, steering cardan shaft UAZ HUNTER (ANDORIA engine, spline) 350 mm, 31512-3401400-20

Manufacturer, steering cardan shaft UAZ 469, HUNTER, BARS d20 (for power steering Borisov) 350 mm, 31512-3401400

Manufacturer, steering cardan for UAZ 452 (for power steering Borisov) SHORT, for wedge, d20 for power steering ShNKF, 3962-3401150

Manufacturer, UAZ steering cardan (for power steering) SHORT d23 (Sterlitamak), 31514-3401150

Manufacturer, Steering cardan joint UAZ 452 (for power steering Borisov) SHORT, for fine spline, d16.2 / d17, 220695-3401150

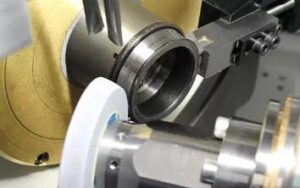

Our Wheel Hubs Production Process

The main process flow of our components (inner and outer flanges and inner rings.)

Inspection & Testing

Full inspection is done at each step of the production process, and faulty parts are not passed on to the next step.

We have a complete set of instruments to test all sizes of the most critical components, including a roundness measuring instrument, profilometer, rough meter, precision altimeter, length measuring device, angle measuring tool, residual magnetometer, etc.

Durable Packaging

Our original reinforced packing method can effectively protect ABS sensors and bolts from damage during transportation

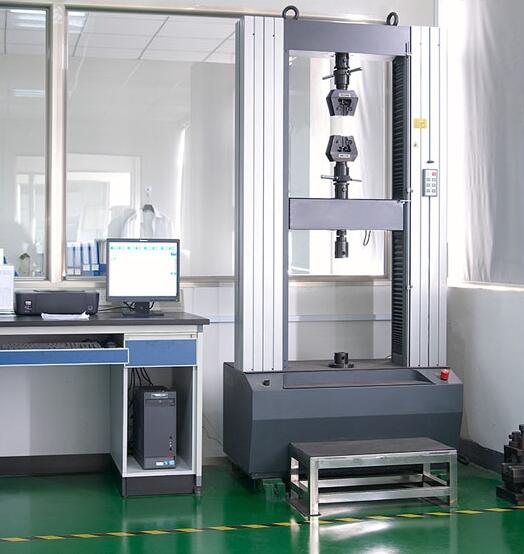

Our Wheel Hub Performance Test Equipments

Not all wheel hubs are the same; let’s talk about our stand-out.

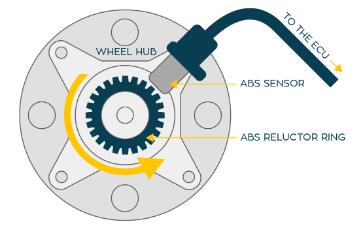

ABS sensor testing

The main purpose of the ABS is to prevent the wheels from locking up, which can lead to a loss of steering control and traction, especially on slippery surfaces. By constantly monitoring the wheel speed and sending this data to the control unit, the ABS sensor helps maintain optimal braking performance, ensuring a safer and more stable driving experience.

Therefore, for these essential safety parts, each product must be fully inspected; any one failed product will not flow into your large goods.

Bolts tensile strength testing

The tensile strength of a bolt is a measure of its ability to resist pulling or tensile forces without breaking. The bolt tensile strength tester is used to determine the maximum amount of tension that a bolt can withstand before it breaks. This information is essential in ensuring that the bolts used in the assembly of wheel hubs are strong enough to withstand the stresses and loads placed on them during operation.

By testing the tensile strength of bolts used in wheel hub assemblies, the bolt tensile strength tester helps to ensure the safety and reliability of the vehicle. Weak or faulty bolts can cause the wheel to come loose while driving, leading to a potentially catastrophic accident.

The bolts we use have a tensile strength of over 1000 Nm, far beyond the competition in the market.

Wheel hub life testing

A life tester in the wheel hub field to test the lifespan and reliability of wheel hub bearings under different loads and speeds. It simulates the fatigue and wear of the bearings under actual operating conditions and provides data to assess their lifespan and reliability. By subjecting bearings to life testing, the expected lifespan of the bearings in actual use can be determined, which helps manufacturers design more durable and reliable wheel hub components, thereby improving vehicle safety and performance.

A low-temperature test has been added to our life tester to test the changes in grease at temperatures as low as -40 degrees to help us use better grease for wheel unit used in various extreme environments.

Clay water endurance testing

A clay water endurance testing machine in the wheel hub field is used to test the water resistance and durability of wheel hub components. This machine simulates real-world conditions where wheel hubs may be exposed to moisture, mud, and other contaminants that can compromise their performance and longevity.

The wheel hub is rotated during the test while submerged in a clay water mixture. This mixture mimics the corrosive and abrasive nature of real-world contaminants that wheel hubs may encounter. In addition, the machine can simulate different temperatures, humidity levels, and other environmental factors to evaluate the wheel hub’s resistance to water and other contaminants.

Each hub assembly undergoes rigorous testing to ensure the bearings are sealed above market standards.

Salty spray testing

This test is designed to simulate harsh environmental conditions, such as exposure to saltwater, which can cause corrosion and deterioration of the components over time.

During the test, the wheel hub is exposed to a saline solution mist for a set period while placed in a controlled environment such as a testing chamber. The wheel hub is inspected for any signs of corrosion, such as rust or pitting, affecting the component’s performance and safety.

By subjecting wheel hub components to salty spray testing, we can evaluate the performance of the products in harsh environmental conditions and make necessary improvements to ensure that our products meet the required performance and durability standards. Ultimately, this helps to ensure the safety and reliability of the wheel hub assemblies used in vehicles, especially in areas where salt or corrosive materials may be present on the road surface, such as coastal areas.

Let's be great together

Unlock Your Competitive Edge: Inquire Now for Unmatched Wheel Hub Solutions!

We have been doing only one thing for the past 13 years. This is to “make good wheel bearings and hub assemblies”; we will continue to do this in the future.

More Advantages

Not all wheel hubs are the same; let’s talk about our stand-out.

High Grade Steel Bearings

Our bearings are high-strength GCR15 steel, subjected to a proprietary process to achieve maximum hardness, and finally treated with a G-10 finish.

High-grade GCR15 steel prevents premature failure due to extreme temperatures and high loads during normal operating conditions. G-10 resin is among the most challenging “glass fiber resins” available. Non-treated steel bearings showed signs of scoring after only a few thousand miles of simulated testing at various speeds. At the same time, treated steel bearings lasted over one hundred thousand miles of simulated testing.

High-Quality Grease

We use Kyodo Yushi AFI grease, made in Japan and specially designed for wheel bearings; it has a long lifespan and performs well in extreme weather.

Without the grease, the best bearing in the world would fail very quickly. So, it’s essential to use high-quality grease that will last the life of the bearing.

Triple & Quadruple Lip Sealing

We use triple and quadruple lip sealing technology. This technique uses high-temperature-resistant rubber to achieve maximum bearing protection against dust, water, and road debris.

10/08F steel plates+NBR rubber.

10.9 Grade Bolts

Our wheel hubs use 10.9-grade bolts; the pulling force can reach 1000 Nm, far exceeding the international standard of 750 Nm. This makes the quality of our bolts much better than other brands in the market.

OEM Specification ABS Sensors

ABS sensors used with our Wheel Hub Assemblies are manufactured with premium wire casings with 99.90% pure copper on the internal wiring for excellent electrical conductivity and optimal performance. In addition, our sensors are rigorously tested using the latest state-of-the-art equipment to ensure that the signal waves meet or exceed OE specs and Electromagnetic Radiation Detectors to detect noise to eliminate radio interference. The chip is imported from Germany.

The ABS Sensors’ sole function is to measure the rotational speed of a wheel and then transmit the collected information to the vehicle’s Engine Control Module (ECM) to assist the anti-lock braking system in controlling the cars driving stability under varying conditions. With premium wire casings, excellent electrical conductivity, and rigorous testing, we can ensure the high performance, durability, and longevity you expect for your vehicle.

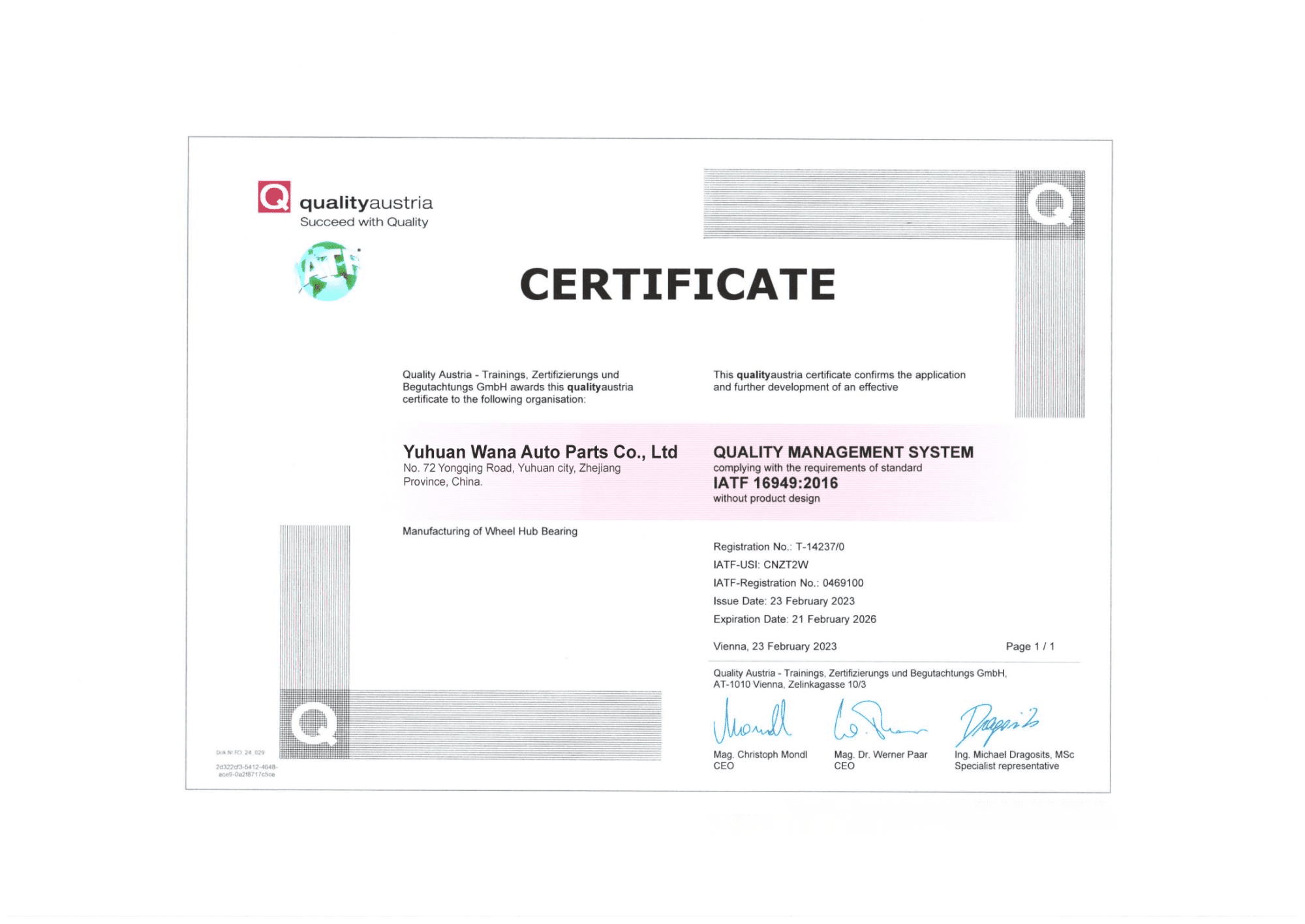

Our Certificate

IATF 16949:2016

Please see our IATF 16949:2016 certificate, which is another reflection of our strength; after all, not all wheel hub factories have the ability to obtain this certificate.

FAQ About Our Wheel Bearing And HUb Assembly

These are the most frequently asked questions. If you cannot find an answer here, please get in touch with us via email.

We are a family business manufacturing located in Yuhuan city, China’s largest automotive chassis parts zone. There are tens of thousands of factories of automotive chassis parts here. So you can find any chassis parts here.

Usually, the minimum order quantity is 200 pcs, because some models we have in stock, and for those we don’t have in stock, the minimum order quantity is 400 pcs.

We offer EXW, FOB, CFR, CIF, and Door to Door delivery terms. All subject to customer requirements.

Accurate factory price, no middle man.

Yes, we offer free samples for your test.

All products from Wana Auto Parts are covered with a 24 Months warranty from the date of installation or 80,000 km, whichever comes earlier.

- Check whether the product pictures are consistent.

- Also, verify that the product OE or standard primary manufacturer number is correct.

- Then, check if the applicable model and year are accurate.

- Finally, check if the product length and mounting dimensions are correct.

Any port in China is ok for us, but the most are Ningbo, Shanghai, Yiwu, Guangzhou, Qingdao etc.

- Pay 30% in advance and 70% before shipment by T.T.

- 100% payment before shipment by T.T.

- 100% payment aginst BL copy by T.T.

- 100% payment 30 days from shipping date by T.T.

Usually, for the models we have, the lead time will be less than 80 days; for newly developed products, the lead time will be 95 days.

All shipment products are documented, and we provide OEM services to many brands without any information about our manufacturer of the goods. Any drawings, operating instructions, test reports, etc., belong to the brand owner.

Yes, custom service is our leading service, tell us your requirements, and we’ll take care of the rest.

Yes, anything you need.

- Provide samples, and we will make drawings, or you can provide us with detailed production drawings.

- Then, make a mold and produce a few roughs.

- Produce pre-production samples and send them to you for confirmation.

- After your side approves the samples, we will start mass production.

- If you do not confirm the sample, we will make changes according to your requirements and resend the sample to you until you approve the sample.

- After the mass production, you can arrange for a third party to inspect the goods, or we will send you samples of large goods for your inspection.

- After you approve, we will ship your goods.

Who paid for the mold, and who owns the mold.