Introduction

Wheel bearings are crucial for any vehicle, ensuring smooth and efficient wheel operation.

They come in two main types: sealed and serviceable. Each type has advantages and disadvantages, making choosing the best option for your automotive application challenging.

This article will discuss the pros and cons of sealed and serviceable wheel bearings, delving deep into each point to help you decide when to select the appropriate bearing type for your wheel hub assembly needs.

Sealed Wheel Bearings: Overview and Function

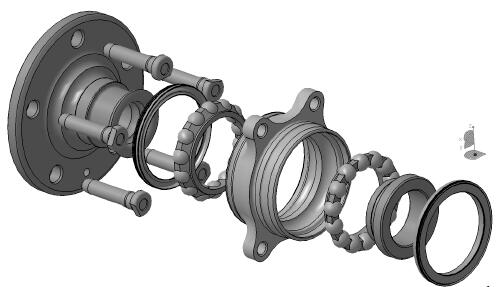

Sealed wheel bearings, also known as cartridge bearings or unitized bearings, are pre-assembled, pre-lubricated, and sealed at the factory.

They come as a complete unit, comprising an inner and outer race, the bearing balls or rollers, and the seals.

These bearings are designed to be maintenance-free, meaning they don’t require periodic lubrication or adjustment.

The primary function of sealed wheel bearings is to reduce friction between the wheel hub and the spindle or axle.

They ensure smooth wheel rotation, minimize wear, and prevent premature failure of other components.

Sealed bearings are commonly used in modern passenger vehicles, offering several advantages over their serviceable counterparts, including ease of installation, reduced maintenance requirements, and longer service life.

However, they also have some disadvantages, such as being non-serviceable and potentially more expensive to replace.

Serviceable Wheel Bearings: Overview and Function

Serviceable wheel bearings, also known as tapered roller bearings or adjustable bearings, are designed to be disassembled, cleaned, and re-greased periodically.

They typically consist of an inner race (cone), an outer race (cup), rollers, and a cage that holds the rollers in place.

These bearings require periodic maintenance, including lubrication and adjustment, to ensure optimal performance and longevity.

The main function of serviceable wheel bearings is similar to that of sealed bearings: they reduce friction between the wheel hub and the spindle or axle.

However, they also provide additional benefits, such as improved load-carrying capacity and adjustability, which can be advantageous in certain applications, such as heavy-duty vehicles and off-road use.

Despite these benefits, serviceable bearings have drawbacks, including increased maintenance requirements and a more complicated installation process.

Pros of Sealed Wheel Bearings

Sealed wheel bearings offer several advantages that make them a popular choice for many automotive applications:

- Reduced Maintenance:

Since sealed bearings are pre-lubricated and sealed at the factory, they require no periodic maintenance.

This eliminates the need for regular inspections, cleaning, and re-greasing, saving time and effort for vehicle owners and technicians.

- Longer Service Life:

The factory seal on sealed bearings helps to keep contaminants, such as dirt and moisture, out of the bearing assembly, reducing wear and prolonging the bearing’s life.

- Easy Installation:

Sealed bearings come as a complete unit, simplifying the installation process.

There is no need to disassemble, clean, and reassemble the bearing components, which can save time and reduce the likelihood of errors during installation.

- Consistent Performance:

Sealed bearings maintain a consistent level of lubrication throughout their service life, ensuring optimal performance and reducing the risk of bearing failure due to inadequate lubrication.

Cons of Sealed Wheel Bearings

Despite their advantages, sealed wheel bearings also have some drawbacks:

- Non-serviceable:

Once a sealed bearing begins to wear or fail, it cannot be serviced or repaired.

The entire bearing unit must be replaced, which can be more expensive than servicing a serviceable bearing.

- Limited Load Capacity:

Sealed bearings may have a lower load-carrying capacity than serviceable bearings, making them less suitable for heavy-duty or off-road applications where increased load capacity is critical.

- Potential for Premature Failure:

Sometimes, the seal on a sealed bearing may fail, allowing contaminants to enter the bearing assembly and cause premature wear or failure.

While this is relatively rare, it can still result in the need for an earlier-than-expected bearing replacement.

Pros of Serviceable Wheel Bearings

Serviceable wheel bearings offer some benefits that make them a viable choice for certain automotive applications:

- Improved Load Capacity:

Due to their design, serviceable bearings often have a higher load-carrying capacity than sealed bearings.

This makes them well-suited for heavy-duty vehicles and off-road applications where increased load capacity is essential.

- Adjustability:

Serviceable bearings can be adjusted to achieve the optimal preload level, ensuring consistent performance and longevity.

- Cost-Effective Repairs:

In bearing wear or damage, serviceable bearings can often be cleaned, re-greased, and reassembled, potentially avoiding a complete replacement.

This can result in cost savings over the long term.

Cons of Serviceable Wheel Bearings

Despite their advantages, serviceable wheel bearings also have some disadvantages:

- Increased Maintenance:

Serviceable bearings require regular maintenance, including inspection, cleaning, and re-greasing.

This can be time-consuming and labor-intensive, especially for vehicle owners needing more skills or tools to perform these tasks.

- More Complex Installation:

The installation process for serviceable bearings can be more complicated than sealed bearings, as it involves disassembling, cleaning, and reassembling the bearing components.

This can increase the likelihood of errors during installation, potentially leading to premature bearing failure or other issues.

- Inconsistent Lubrication:

Over time, the grease in a serviceable bearing may break down or become contaminated, resulting in inconsistent lubrication and an increased risk of bearing failure.

Regular maintenance is crucial to ensure optimal performance and longevity.

Choosing the Right Bearing Type for Your Application

When selecting the appropriate bearing type for your wheel hub assembly, it is essential to consider the specific requirements of your automotive application, as well as the pros and cons of each bearing type:

- Vehicle Type:

Consider the type of vehicle and its intended use. Sealed bearings are generally more suitable for passenger vehicles, while serviceable bearings may be a better option for heavy-duty or off-road applications.

- Maintenance Preferences:

If you prefer a low-maintenance option, sealed bearings may be the better choice.

However, if you are willing to invest the time and effort in regular maintenance, serviceable bearings offer better long-term performance and cost savings.

- Load Capacity:

Determine the load capacity requirements of your application. Serviceable bearings may be better suited for applications that require increased load capacity, while sealed bearings may suffice for lighter-duty applications.

- Cost:

Weigh the initial cost of each bearing type against the potential long-term cost savings.

Sealed bearings may have a higher upfront cost but may save money in the long run due to reduced maintenance requirements.

Serviceable bearings may have a lower initial cost but may require more frequent maintenance and repairs.

Technological Developments and the Future of Wheel Bearings

As automotive technology evolves, wheel bearing design and materials innovations will likely emerge, potentially impacting the choice between sealed and serviceable bearings.

- Advanced Materials:

Materials science development may lead to more durable and wear-resistant bearing materials, prolonging the service life of both sealed and serviceable bearings.

Additionally, advances in lubricant technology could result in longer-lasting and more effective grease formulations, reducing the maintenance requirements of serviceable bearings.

- Integrated Sensors:

Integrating sensors within wheel bearing assemblies can offer real-time monitoring of bearing performance and wear, potentially allowing for predictive maintenance and reducing the risk of bearing failure.

This technology could be applied to sealed and serviceable bearings, enhancing their performance and reliability.

- Sealed Bearing Serviceability:

Innovations in sealed bearing design may eventually enable these bearings to be serviceable, combining the advantages of sealed and serviceable bearings into a single, versatile product.

This could revolutionize the automotive wheel bearing market, offering vehicle owners and technicians the best of both worlds in maintenance and performance.

Conclusion

In conclusion, as automotive technology advances, vehicle owners, technicians, and manufacturers must stay informed about the latest developments in wheel bearing technology.

By understanding the evolving landscape of wheel bearings and considering the specific needs of each application, industry professionals can make informed decisions that contribute to safer, more efficient, and higher-performing vehicles.