Introduction:

In the intricate world of automotive engineering, even the minutest details can profoundly influence a vehicle’s performance, safety, and overall driving experience.

One such critical aspect is the balancing of the wheel hub assembly. At Wana Auto Parts Co., Ltd., knowledge dissemination is pivotal.

This article sheds light on the significance of wheel hub assembly balancing, its scientific basis, and its far-reaching implications on vehicle performance.

1. Wheel Hub Assembly Balancing: A Brief Overview

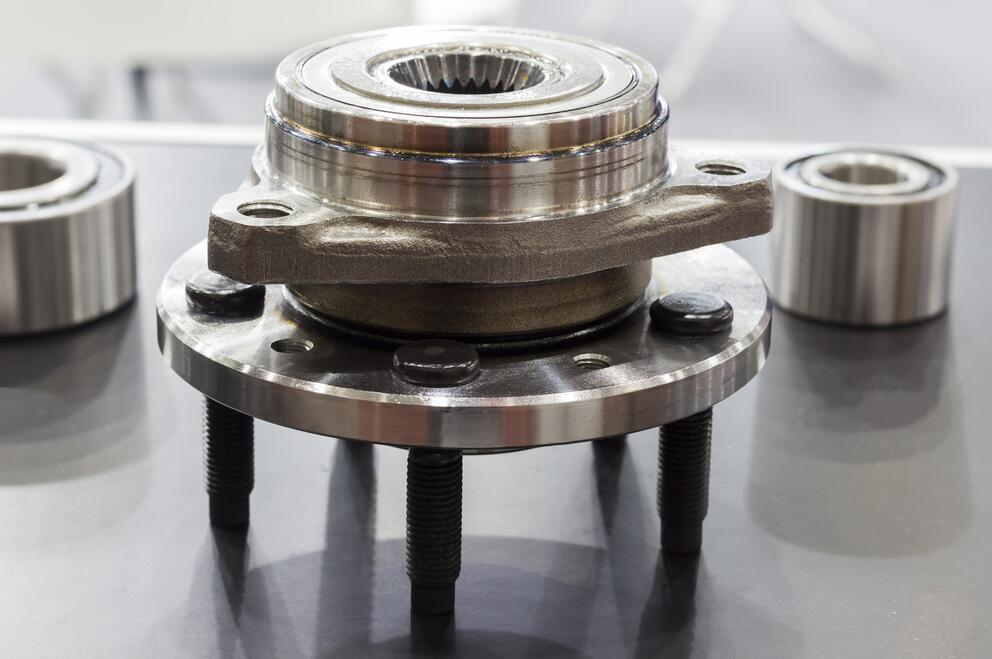

The wheel hub assembly forms the core of a wheel’s rotation.

When we speak of its balancing, we refer to the even distribution of weight around its axis of rotation.

Any imbalance, even if minute, can lead to vibrations, uneven tire wear, and compromised safety.

Significance: A balanced wheel hub assembly ensures a smooth driving experience, minimizes wear and tear, and enhances vehicle safety.

Methods: Wheel hub assembly balancing is typically achieved through two main ways – static (single-plane) and dynamic (dual-plane).

Both have their unique procedures and applications.

2. Static (Single-Plane) Balancing

Static balancing addresses weight discrepancies in one plane – the vertical plane.

Here, the goal is to ensure the wheel doesn’t have a heavier segment that could cause it to rotate when left unattended on a balancing machine.

Methodology: The wheel hub assembly is placed on a vertical, non-motorized spindle.

If the body rotates and stops with a particular section at the bottom consistently, it indicates an imbalance.

Correction: Small weights are added to the lighter side of the wheel until it remains stationary in any position on the spindle.

Application: While essential, static balancing is often a preliminary step before dynamic balancing in modern wheel services.

3. Dynamic (Dual-Plane) Balancing

Unlike static balancing, dynamic balancing addresses imbalances in two planes – both vertical and horizontal.

Methodology: The wheel hub assembly is mounted on a motorized spindle with sensors.

These sensors detect imbalances in vertical and horizontal planes as the group spins.

Correction: Weights are meticulously added to correct imbalances in both planes, ensuring a well-balanced rotation.

Significance: Dynamic balancing is crucial for modern vehicles, especially those that operate at higher speeds. It ensures a vibration-free ride and minimizes tire wear.

4. Implications of a Poorly Balanced Wheel Hub Assembly

The repercussions of neglecting wheel hub assembly balancing are manifold.

Vibrations: The most immediate and noticeable consequence is vibration, especially at specific speeds.

This not only compromises comfort but also affects vehicle control.

Tire Wear: Imbalances in the wheel hub assembly lead to uneven tire wear. This not only shortens tire lifespan but also can compromise grip and safety.

Bearing Strain: Imbalances exert undue stress on wheel bearings, potentially reducing their operational lifespan and compromising their efficacy.

5. The Technological Evolution in Balancing

Over the decades, wheel hub assembly balancing science has witnessed transformative technological advancements.

Sensing Technology: Modern balancers employ cutting-edge sensors that detect even the slightest imbalances with incredible precision.

Automated Corrections: Some advanced machines automatically determine the exact weight needed and its optimal placement, ensuring impeccable balancing with minimal human intervention.

Integrated Solutions: With the advent of connected technologies, modern balancers can integrate with workshop management systems, streamlining operations and maintaining a digital footprint of each service.

6. The Human Touch: Expertise Matters

While technology has revolutionized wheel hub assembly balancing, the role of human expertise remains paramount.

Diagnosis: Experienced technicians can often diagnose an imbalance by interpreting the vibration patterns or observing tire wear.

Precision: Even with the most advanced balancers, placing corrective weights requires a deft touch, ensuring they stay affixed and perform their role over time.

Continual Learning: As wheel hub assemblies and balancing technologies evolve, technicians need to stay up-to-date with the latest methodologies and best practices.

7. The Role of Materials in Wheel Hub Assembly Balancing

Material consistency and quality play an undeniable role in wheel hub assembly balancing. Here’s why:

Uniformity: The uniformity of material distribution is crucial. Any discrepancies can lead to natural imbalances, even before the assembly sees any wear or external influences.

Durability: The materials used must withstand the rigors of continuous rotation, temperature fluctuations, and potential impact. Inferior materials can warp, which affects balance over time.

Weight Management: The introduction of lightweight, high-strength materials has reduced the overall weight of wheel hub assemblies.

This has implications for balancing, as lighter components can be more sensitive to minor imbalances.

8. Real-World Impacts: Beyond the Lab

While balancing equipment in controlled environments is incredibly precise, real-world factors can introduce challenges.

Road Conditions: Potholes, bumps, and rough terrains can dislodge balancing weights or alter the assembly’s balance through physical impacts.

Temperature Variations: Extreme cold or heat can affect material properties, potentially influencing balance.

Wear and Tear: As the wheel hub assembly experiences wear over time, its balance can naturally change.

Regular check-ups ensure that equilibrium is maintained throughout the assembly’s life.

9. Future Trends in Wheel Hub Assembly Balancing

The automotive world is in continuous flux, and balancing practices aren’t immune to this evolution.

Adaptive Balancing Systems: Imagine a real-time system that can detect and correct imbalances without human intervention.

With the rise of intelligent vehicles and IoT, adaptive balancing systems might soon become a reality.

Eco-friendly Weights: As the automotive industry shifts towards sustainability, there’s a push for using recyclable or eco-friendly materials for balancing weights.

Integrated Diagnostics: Future vehicles might have diagnostic systems that notify drivers of imbalance issues, prompting timely checks and maintenance.

10. Emphasizing Regular Maintenance and Checks

Balancing isn’t a one-time task. Over a vehicle’s lifetime, several factors can impact the wheel hub assembly’s balance.

Scheduled Checks: Regularly scheduled balancing checks, especially after any notable impact or when vibrations are felt, can extend the life of the assembly and ensure optimal performance.

Professional Expertise: While advanced tools play their role, relying on seasoned professionals for balancing tasks is crucial.

Their expertise can often spot issues before they become significant problems, ensuring a smooth driving experience.

Conclusion:

While seemingly a minute detail in the grand tapestry of automotive engineering, wheel hub assembly balancing holds immense importance.

Ensuring optimal balance isn’t just about comfort, safety, performance, and longevity.

At Wana Auto Parts Co., Ltd., we champion the blend of cutting-edge technology with human expertise.

As Orde Yuan leads the helm, our commitment remains steadfast: delivering unparalleled quality, one revolution at a time.