Introduction

The wheel hub assembly and bearing industry is a critical component of the automotive sector, with safety and performance being paramount considerations.

As global demand for these essential parts grows, manufacturers must uphold the highest industry standards.

This case study delves into the best practices employed by leading manufacturers in the sector, examining the factors contributing to their success in producing high-quality products and ensuring customer satisfaction.

Embracing Cutting-Edge Technologies and Techniques

One of the defining characteristics of industry-leading manufacturers is their ability to incorporate cutting-edge technologies and techniques into their production processes.

Innovations such as automation, advanced manufacturing techniques, and implementing Industry 4.0 technologies have enabled these companies to achieve unparalleled efficiency and precision in their operations.

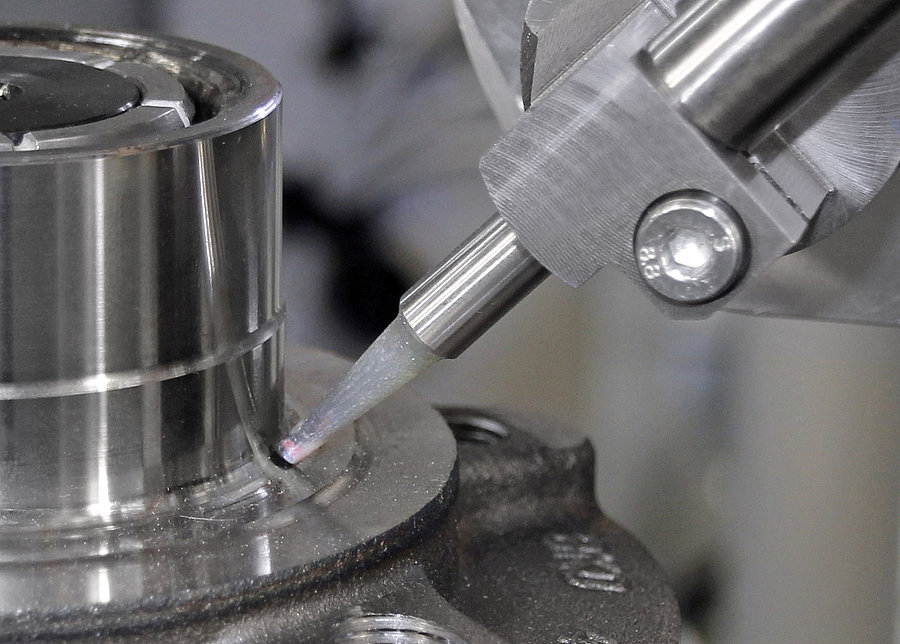

For example, computer numerical control (CNC) machines are now widely used in producing wheel hub assemblies and bearings.

These machines allow for greater accuracy and repeatability, ensuring that each component produced meets the strictest quality standards.

Additionally, manufacturers are leveraging additive manufacturing techniques, such as 3D printing, to create complex prototypes and small production runs, reducing the time and cost associated with traditional manufacturing methods.

Another notable trend is the increasing adoption of collaborative robots, or cobots, which work alongside human operators to enhance productivity and safety.

Manufacturers can automate repetitive tasks by integrating robots into their production lines, freeing their skilled workforce to focus on more complex, value-added activities.

Moreover, smart factories equipped with interconnected devices and advanced analytics capabilities are revolutionizing the industry.

These facilities enable real-time data collection and analysis, allowing manufacturers to optimize operations, reduce waste, and enhance productivity.

Commitment to Research and Development

A strong commitment to research and development (R&D) is a critical factor in the success of leading manufacturers.

By investing in R&D initiatives, these companies can continuously refine their existing products and develop new solutions tailored to the evolving needs of the automotive industry.

For instance, industry leaders often collaborate with research institutions and universities to access cutting-edge knowledge and resources.

These partnerships can develop innovative materials and manufacturing processes that improve wheel hub assemblies and bearings’ performance, durability, and efficiency.

Furthermore, some manufacturers have established dedicated in-house R&D departments or innovation centers staffed by engineering, materials science experts, and other relevant fields.

These specialized teams work relentlessly to develop new products and explore emerging technologies, such as nanotechnology, which has the potential to revolutionize the industry by enabling the creation of ultra-durable, lightweight, and energy-efficient bearings.

Another critical aspect of R&D is the focus on reducing environmental impact.

Many leading manufacturers are developing eco-friendly production methods and materials, such as biodegradable lubricants and recycled metals, to minimize their carbon footprint and cater to the growing demand for sustainable products.

Collaboration with Industry Stakeholders

Working closely with key industry stakeholders, such as automotive OEMs and suppliers, is essential for leading manufacturers to gain insights into current and future market requirements.

Strategic partnerships and collaborations allow companies to understand customer needs and preferences better, enabling them to design and produce wheel hub assemblies and bearings that offer optimal performance and durability.

For example, manufacturers can gain invaluable information on specific requirements and constraints by collaborating with OEMs during the design phase of a new vehicle.

This close cooperation enables them to develop tailor-made solutions that integrate seamlessly with the vehicle’s overall design and performance goals.

Additionally, partnering with suppliers can lead to developing advanced materials and components, further enhancing the quality and performance of the final products.

These relationships also facilitate more efficient supply chain management, ensuring a steady flow of raw materials and components required for production.

Moreover, collaborating with technology providers allows manufacturers to access cutting-edge innovations and integrate them into their operations.

For example, partnering with companies specializing in advanced robotics, IoT, and data analytics can help manufacturers optimize their production processes, reduce downtime, and increase overall efficiency.

These strategic collaborations contribute to developing superior wheel hub assemblies and bearings and foster long-lasting relationships with key industry players, driving mutual growth and success.

Implementing Sustainable Manufacturing Practices

As the automotive industry increasingly focuses on sustainability, leading wheel hub assemblies and bearings manufacturers implement eco-friendly manufacturing practices.

By adopting sustainable production methods, these companies can minimize their environmental footprint and cater to the growing demand for environmentally responsible products.

One approach involves optimizing energy consumption by implementing energy-efficient machinery and equipment, such as variable frequency drives, LED lighting, and energy management systems.

These technologies can help manufacturers reduce their energy usage, lowering operating costs and greenhouse gas emissions.

Another critical aspect of sustainable manufacturing is waste reduction.

Leading manufacturers employ lean manufacturing principles and techniques, such as the 5S system, Six Sigma, and Total Quality Management (TQM), to identify and eliminate waste within their production processes.

Manufacturers can reduce their environmental impact by minimizing waste generation and recycling materials wherever possible.

Moreover, sustainable manufacturers often use renewable energy sources, such as solar panels and wind turbines, to power their facilities.

By transitioning to clean energy, these companies can significantly reduce their reliance on fossil fuels and decrease carbon emissions.

Lastly, investing in employee training and awareness programs ensures that the workforce understands the importance of sustainability and adopts eco-friendly practices in their daily operations.

This commitment to sustainability can improve the company’s environmental performance and enhance its reputation among customers and stakeholders.

Maintaining Stringent Quality Assurance Measures

For wheel hub assembly and bearing manufacturers, ensuring product quality is paramount due to these components’ critical role in vehicle safety and performance.

Leading manufacturers implement stringent quality assurance measures throughout their production processes to guarantee that every product meets the highest industry standards.

To begin with, these companies often establish comprehensive quality management systems, such as ISO 9001 or IATF 16949, to ensure consistent quality across all operations.

These systems provide a structured framework for managing and improving processes, reducing errors, and enhancing overall product quality.

In addition to adhering to recognized quality standards, leading manufacturers employ advanced inspection and testing equipment to verify the quality and performance of their products.

This equipment can include coordinating measuring machines (CMMs), hardness testers, and vibration analysis tools, which enable manufacturers to perform precise measurements and detect any potential defects or deviations from specifications.

Furthermore, these companies often implement robust traceability systems to track components and materials throughout their production processes.

This traceability enables manufacturers to quickly identify and resolve quality issues, minimizing the risk of defective products reaching customers.

By maintaining strict quality assurance measures, leading manufacturers can ensure the production of high-quality wheel hub assemblies and bearings that meet or exceed customer expectations.

Focusing on Talent Development and Retention

Attracting, developing, and retaining top talent is crucial for manufacturers to maintain their competitive edge in the wheel hub assembly and bearing industry.

Leading manufacturers invest in comprehensive training and development programs to equip their workforce with the necessary skills and knowledge to excel in their roles.

These programs can include hands-on technical training, workshops, and seminars covering advanced manufacturing techniques, lean principles, and emerging technologies.

Manufacturers can ensure their operations remain at the forefront of industry innovation by providing employees with continuous learning and growth opportunities.

Moreover, leading manufacturers often implement employee engagement initiatives, such as mentorship programs, team-building activities, and performance-based incentives, to foster a positive and motivating work environment.

These initiatives can help to improve employee satisfaction, productivity, and loyalty, ultimately contributing to the company’s overall success.

In addition to investing in employee development, leading manufacturers recognize the importance of cultivating a diverse and inclusive workforce.

By promoting diversity and inclusion, these companies can tap into a broader range of perspectives, experiences, and ideas, fueling innovation and driving better business outcomes.

Furthermore, companies that prioritize talent development and retention can attract top talent in a competitive labor market.

By offering competitive compensation packages, comprehensive benefits, and opportunities for career advancement, these manufacturers can position themselves as employers of choice within the industry.

Emphasizing Customer-Centricity

In today’s competitive market, customer-centricity is essential for manufacturers to differentiate themselves and build lasting relationships with their clients.

Leading wheel hub assemblies and bearings, manufacturers strongly emphasize understanding and addressing their customers’ unique needs and preferences.

One way in which these manufacturers prioritize customer-centricity is by offering customized solutions tailored to specific client requirements.

By working closely with customers during the design and development process, manufacturers can create products that perfectly align with their client’s expectations and performance criteria.

Another critical aspect of customer-centricity is providing exceptional after-sales support.

Leading manufacturers often establish dedicated customer service teams to address any concerns or issues clients may encounter with their products.

This support can include troubleshooting assistance, product replacement or repair, and warranty services.

Moreover, top manufacturers actively seek and analyze customer feedback to identify areas for improvement and ensure their products continue to meet evolving customer needs.

Manufacturers can enhance customer satisfaction and maintain a strong market position by incorporating customer insights into product development and improvement efforts.

Leveraging Digital Marketing and E-commerce

In the age of digitalization, leading manufacturers of wheel hub assemblies and bearings are harnessing the power of digital marketing and e-commerce to reach new customers and drive growth.

By establishing a robust online presence, these companies can showcase their products and expertise to a global audience and generate valuable leads.

A successful digital marketing strategy’s key component is a user-friendly, informative website highlighting the company’s product offerings, capabilities, and unique selling propositions.

Leading manufacturers often invest in search engine optimization (SEO) and content marketing to increase their visibility in search results and attract potential customers.

In addition to having an effective website, top manufacturers leverage social media platforms like LinkedIn, Facebook, and Instagram to engage with their target audience and share valuable content.

By creating and sharing informative articles, videos, and case studies, these companies can demonstrate their industry expertise and establish themselves as thought leaders in the wheel hub assembly and bearing space.

Furthermore, embracing e-commerce allows manufacturers to broaden their reach and cater to the growing demand for online purchasing.

By offering their products through online marketplaces or e-commerce platforms, manufacturers can tap into new market segments and provide customers with a seamless, convenient shopping experience.

Conclusion

By implementing these best practices, leading wheel hub assembly and bearing industry manufacturers can maintain a competitive edge, ensure product quality and safety, and foster long-term growth.

From embracing cutting-edge technologies to prioritizing customer-centricity, these strategies can serve as a roadmap for companies seeking to excel in this dynamic and competitive market.